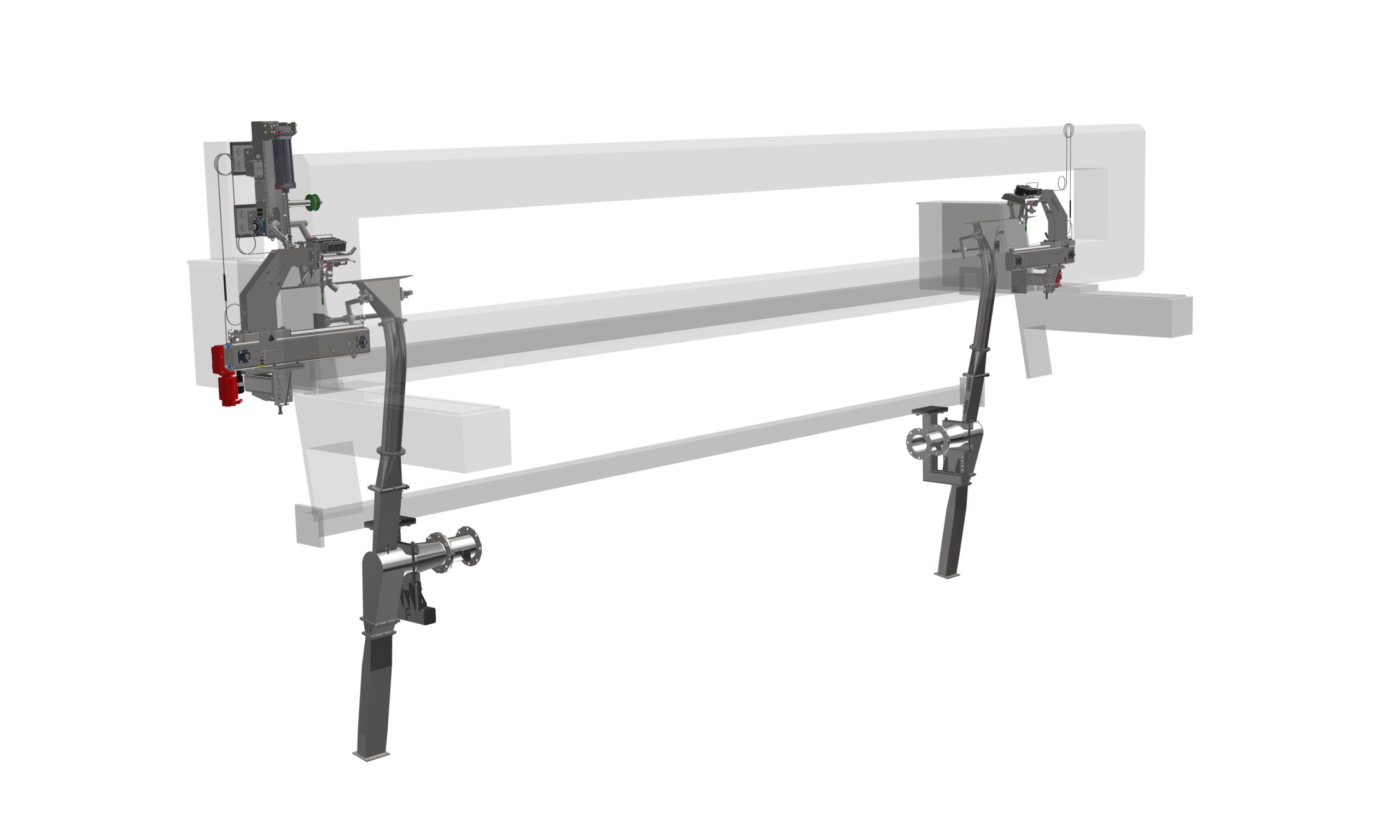

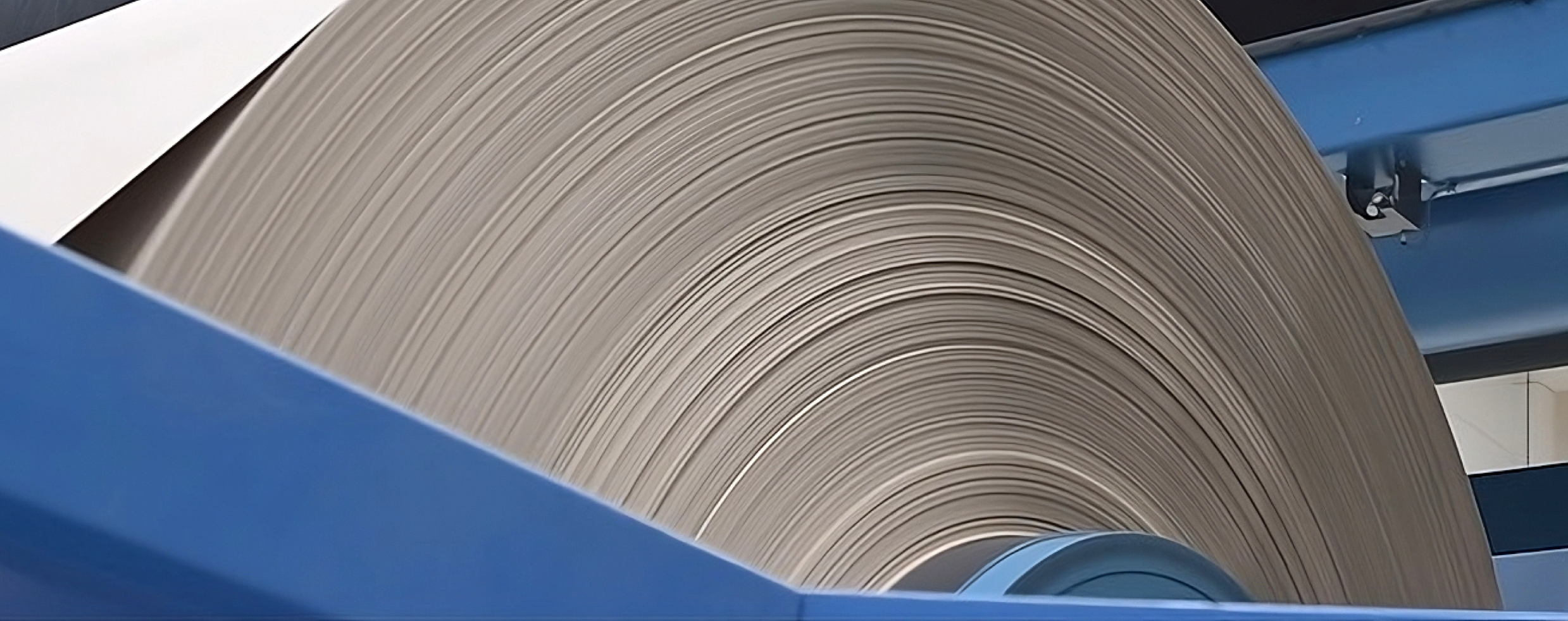

A paper edge trim unit plays a crucial role in the paper-making process by removing poor-quality or cracked edges, correcting uneven edge moisture, and producing consistent, precise web widths at any point along your online or offline processes. Furthermore, the waste generated during trimming can be efficiently returned directly to the nearest pulper or a remote broke chest, minimizing waste and maximizing resource utilization.

The Trim-Jet™ P edge trim unit provides a highly effective solution for creating a stable, high-quality edge in the cross-machine direction, overcoming the challenges posed by a sideways-moving web. By using the Trim-Jet™ P, you can wind rolls with perfectly aligned edges and prevent coating materials from seeping through gaps, avoiding contamination on the sheet or its backing during coater application. In addition, the system maintains a fixed edge through calender and supercalender processes, reducing heat stress on the roll cover and eliminating uneven sheet edge caliper.

Features | Paper Edge-Trimming System

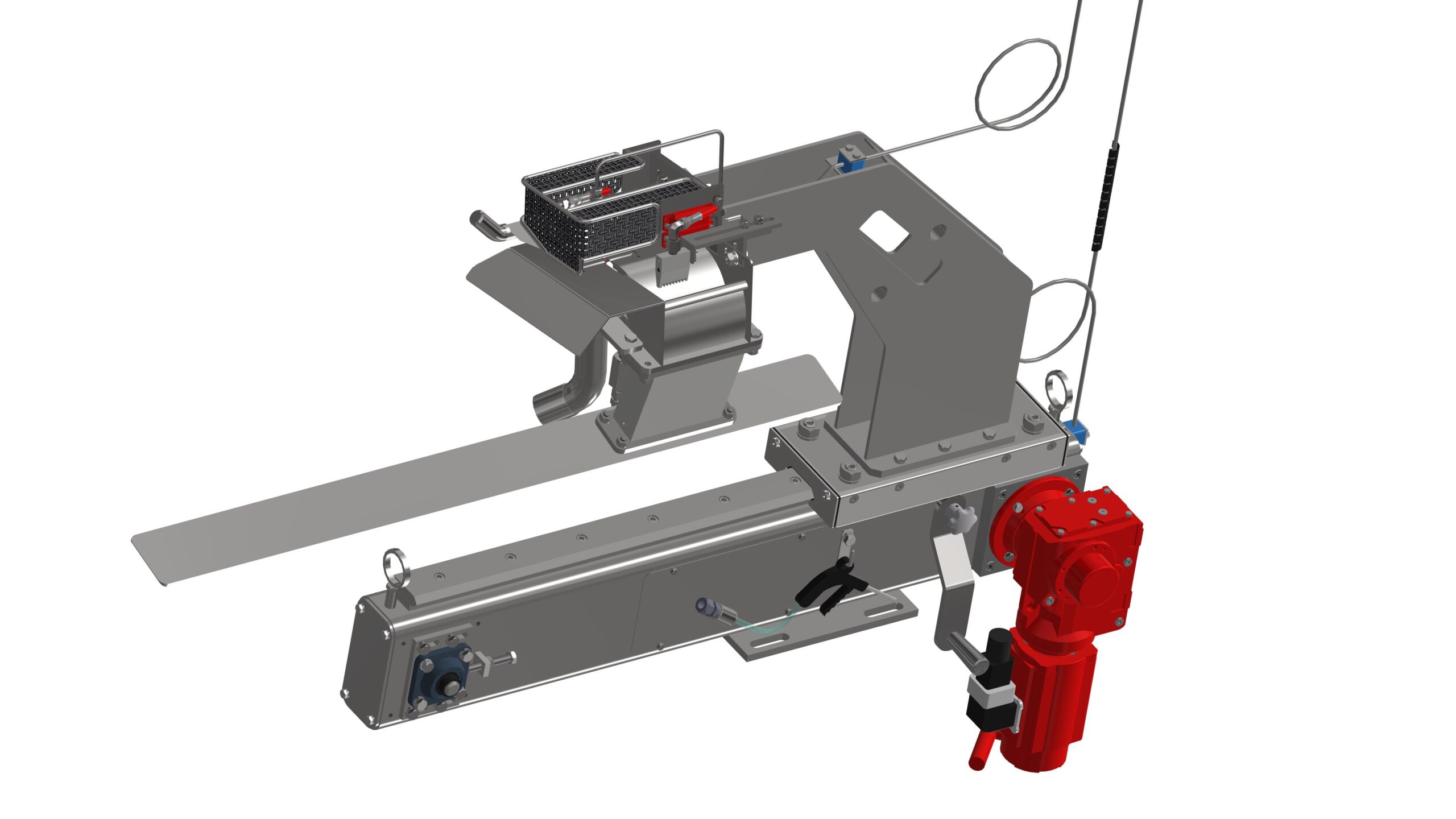

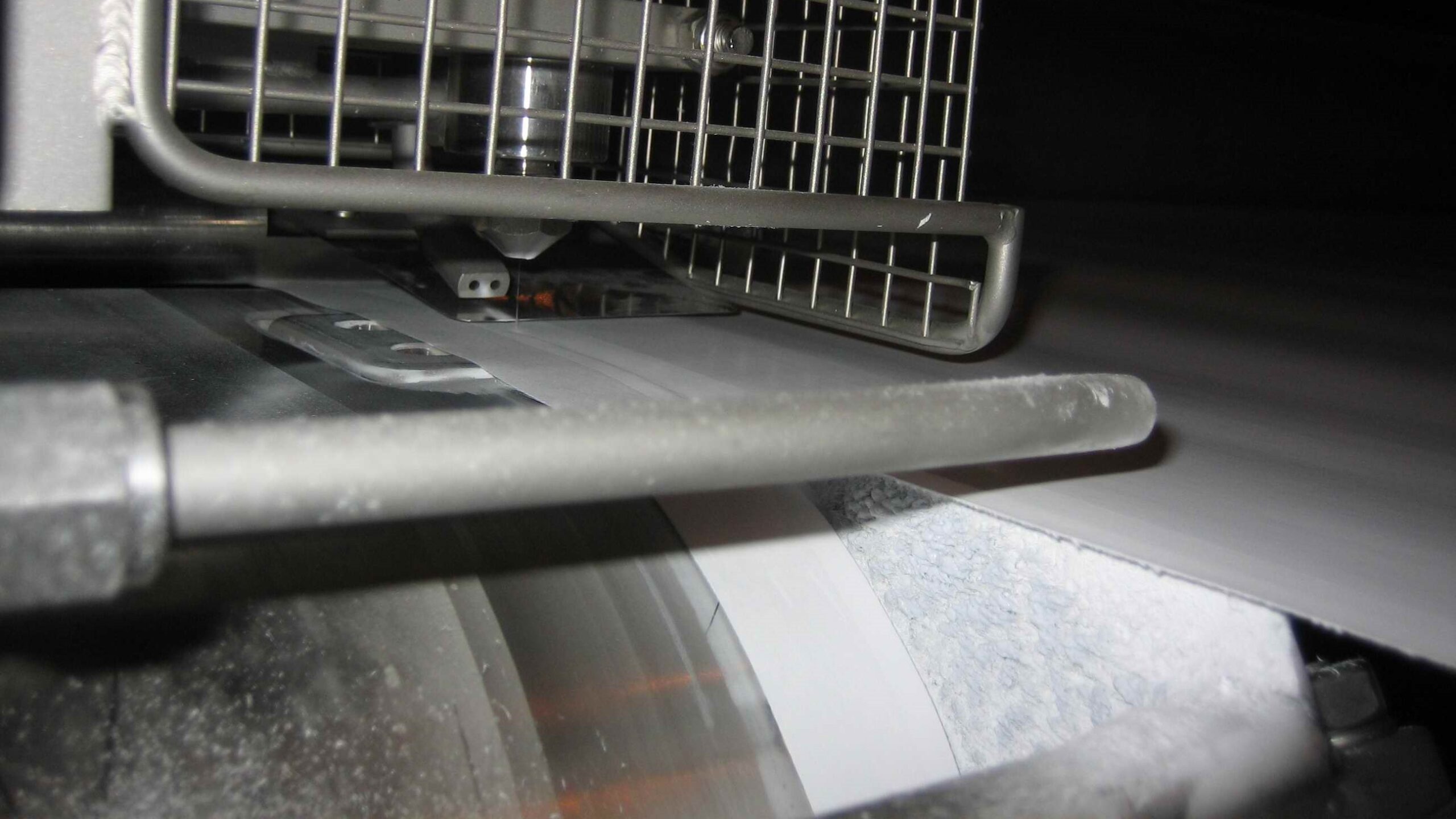

- Cut paper sheet edge trims as small as 15mm (0.6”) and up to 150mm (6”) or higher

- Can handle and convey paper edge trims using compressed air or a blower fan

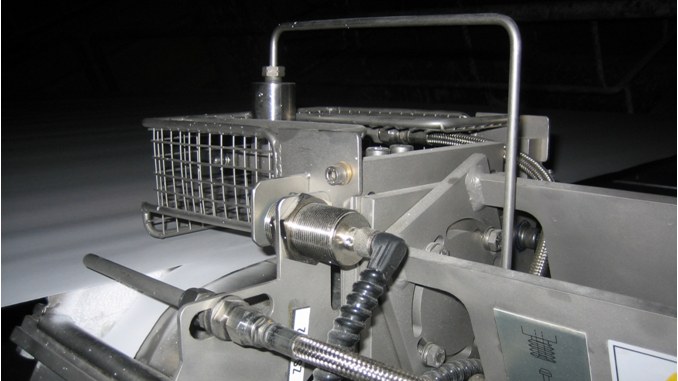

- Stainless steel construction

- Diamond cutting nozzles for reliable jets and long-life

- Can be installed where ropes are present

Advantages | Paper Edge-Trimming System

- Able to engage into any sheet edge quality to initiate any pre-set trim removal width

- Can effectively trim an oscillating sheet to produce a high-quality fixed-edge

- Eliminates forming paper edge defects that may lead to sheet breaks

- Not affected by sheet speed, moisture, caliper, or tension

ROI

- Able to sustain narrow trim down to 15mm (0.6″) for maximum product on the reel

- Production costs are significantly improved as only rolls with hole defects or requiring splicing must be re-reeled

- Increased machine speed

- Sheet edges are directed to the machine pulper, bypassing any broke chest

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.