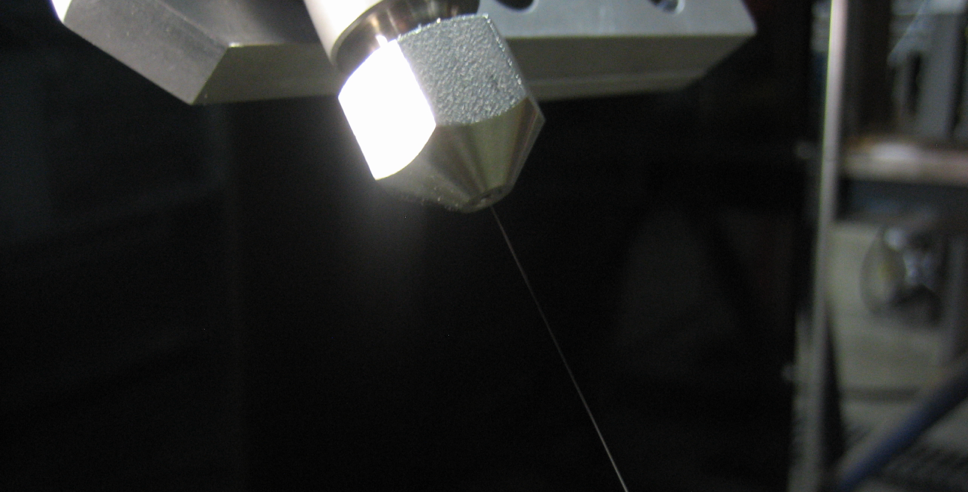

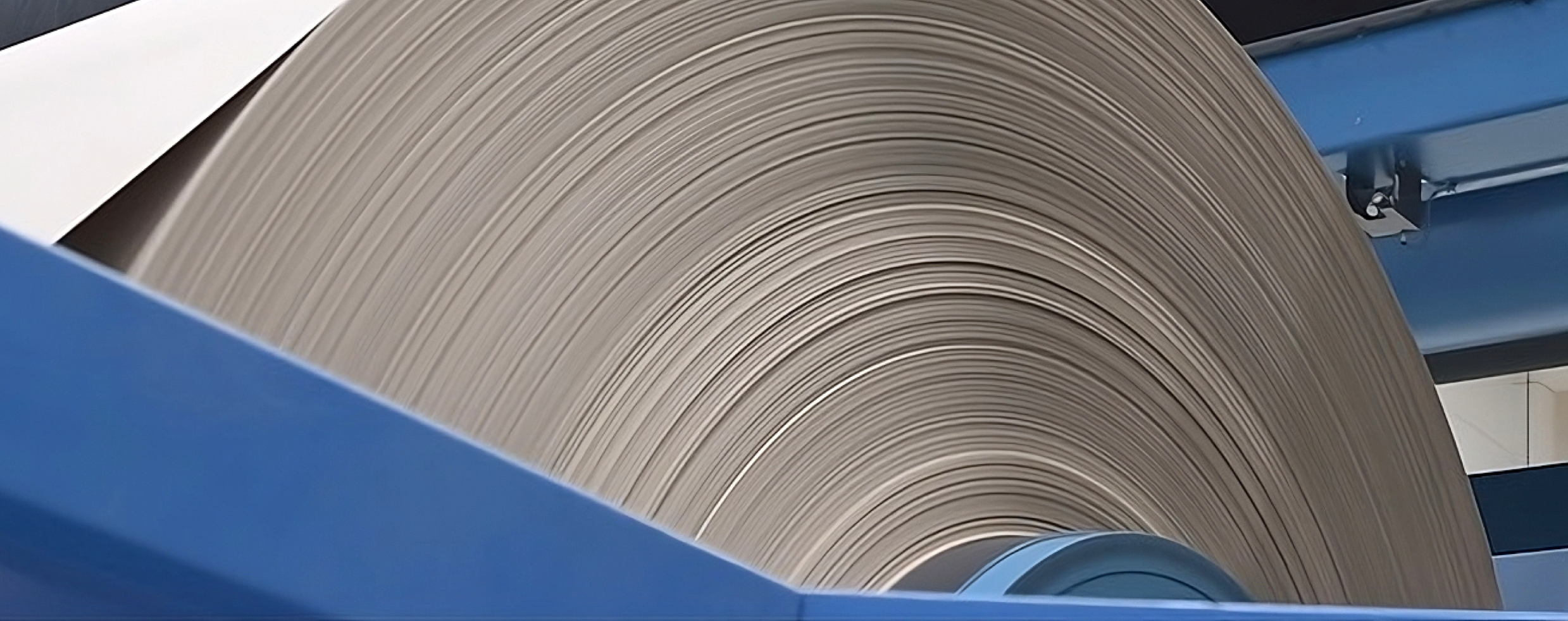

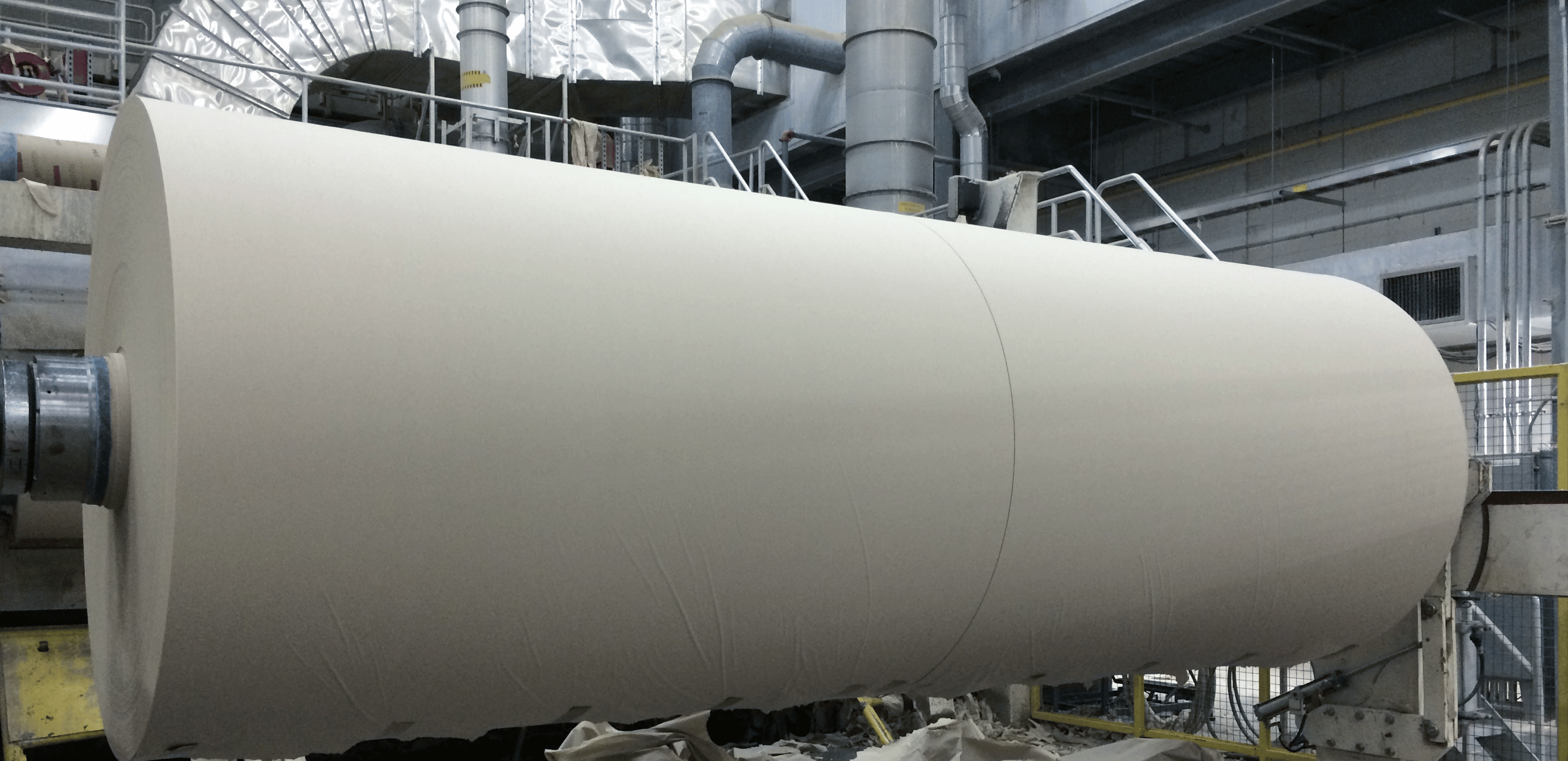

With over 35 years of expertise, Paprima was the first to introduce high-pressure water-jet technology to the Pulp and Paper industry worldwide and has further developed this technology for today’s most challenging applications.

Explore Our ProductsThe Industry Leader in High-Pressure Water-Jet Solutions

Leading with Innovation, Sustainability, Reliability and Excellence

Paprima’s industry-leading products have been installed in over 700 systems globally, making us the trusted name in the industry. Our team of experts delivers tailor-made solutions that meet the industry’s most demanding applications.

Industry Transformation

Revolutionizing the Pulp and Paper industry through innovation and sustainability allows our customers to optimize processes and set new benchmarks.

Global Presence

As the global leader in water-jet technology, our team of experts offers solutions for machines worldwide.

Trusted Reputation

Top tissue, paper and board manufacturers and paper machine OEMs trust Paprima due to their reputation for providing the highest quality equipment.

Spread Out Across Multiple Countries, Provinces, and States Worldwide.

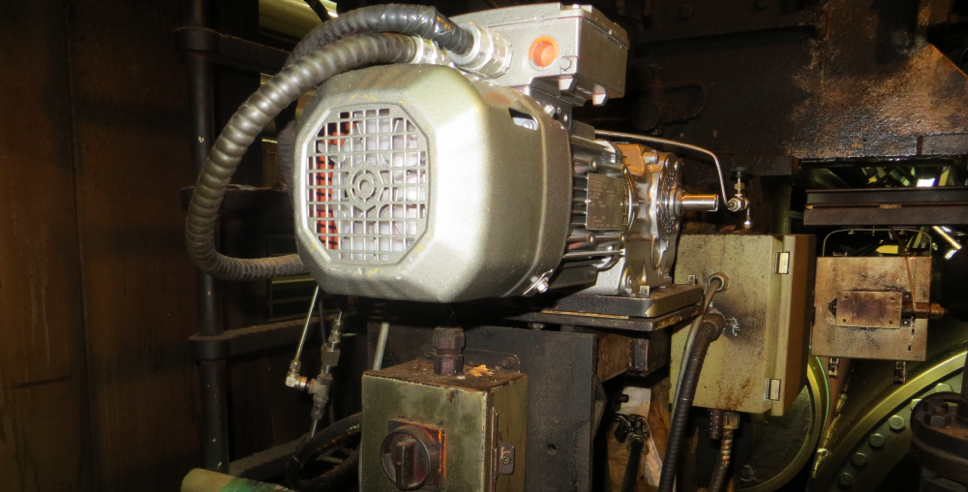

Equipment Engineered for Reliability & Durability

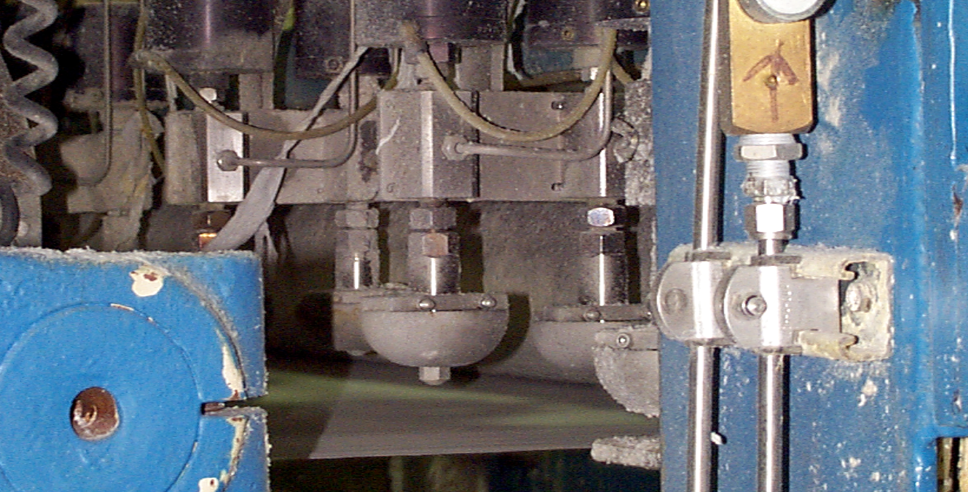

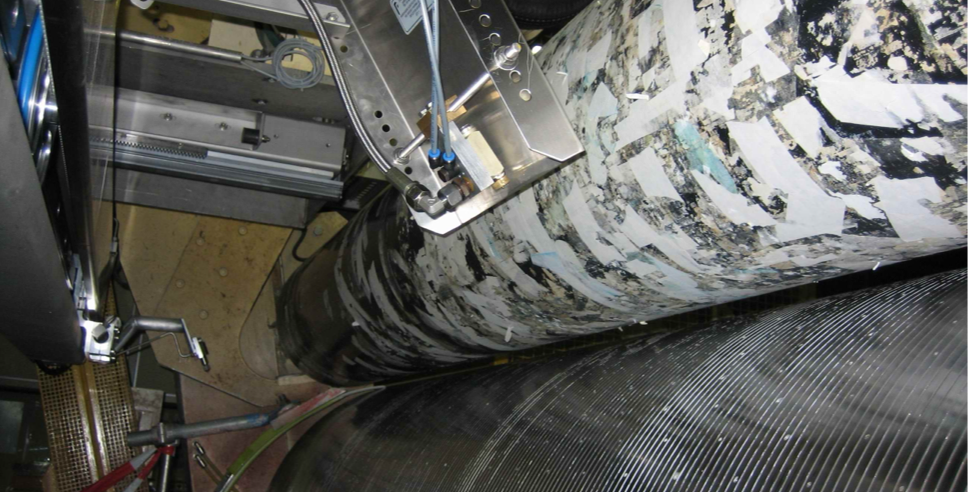

Since 1989, Paprima has been a pioneer in the industry, with our tail cutter being the first of its kind. Today, it is still being used, a testament to the durability and reliability of our machinery. Paprima has been transforming the industry with our cutting-edge solutions, including our tail cutters, turn-up systems, edge trimming and slitting systems, and dryer fabric cleaners. Our commitment to innovation and excellence is what sets us apart from the competition. Choose Paprima for machinery that is built to last.

Transform your production efficiency with our state-of-the-art equipment technology. With Reel-Jet, you can minimize core loss and enhance turn-up efficiency, while Power-Jet ensures that your fabrics are always clean and maintain fabric permeability. Trim-Jet guarantees top-quality finish by enabling precise water-jet slitting and edge-trimming. And with Jet-X 2000, you can enjoy uninterrupted cutting, improving your overall productivity.

Explore Our Products

Continuous Improvement and Research & Development

At Paprima Industries, we believe in relentless progress and innovation. Our journey towards excellence is paved with a strong dedication to continuous improvement and cutting-edge Research and Development (R&D). We constantly strive to elevate our solutions to new heights, aligning with the evolving needs and technological advancements of the Pulp and Paper Industry.

Approach to Continuous Improvement

In an ever-changing industrial landscape, we embrace the philosophy of continuous improvement. Our teams meticulously analyze our products, processes, and customer feedback to identify areas for enhancement. Through an agile approach, we implement refinements and updates to our offerings, ensuring they remain at the forefront of efficiency, reliability, and sustainability.

Process Development Facility

We understand how crucial it is to test new applications before putting them into use. That’s why we have our own cutting testing and process development facility. Our experts conduct rigorous tests on behalf of our clients to ensure our equipment meets their desired specifications. With Paprima, you can be confident that your applications will be thoroughly tested and optimized for maximum performance.

Future-Forward Thinking

We are constantly seeking ways to enhance our equipment and increase the time between service intervals. We firmly believe that remote monitoring will benefit our clients in the long run by enabling us to predict downtimes, which can lead to significant cost savings for mills. Our ultimate aim is to install sensors on all of our equipment to accurately forecast when they will be due for maintenance.

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.