Open Draw

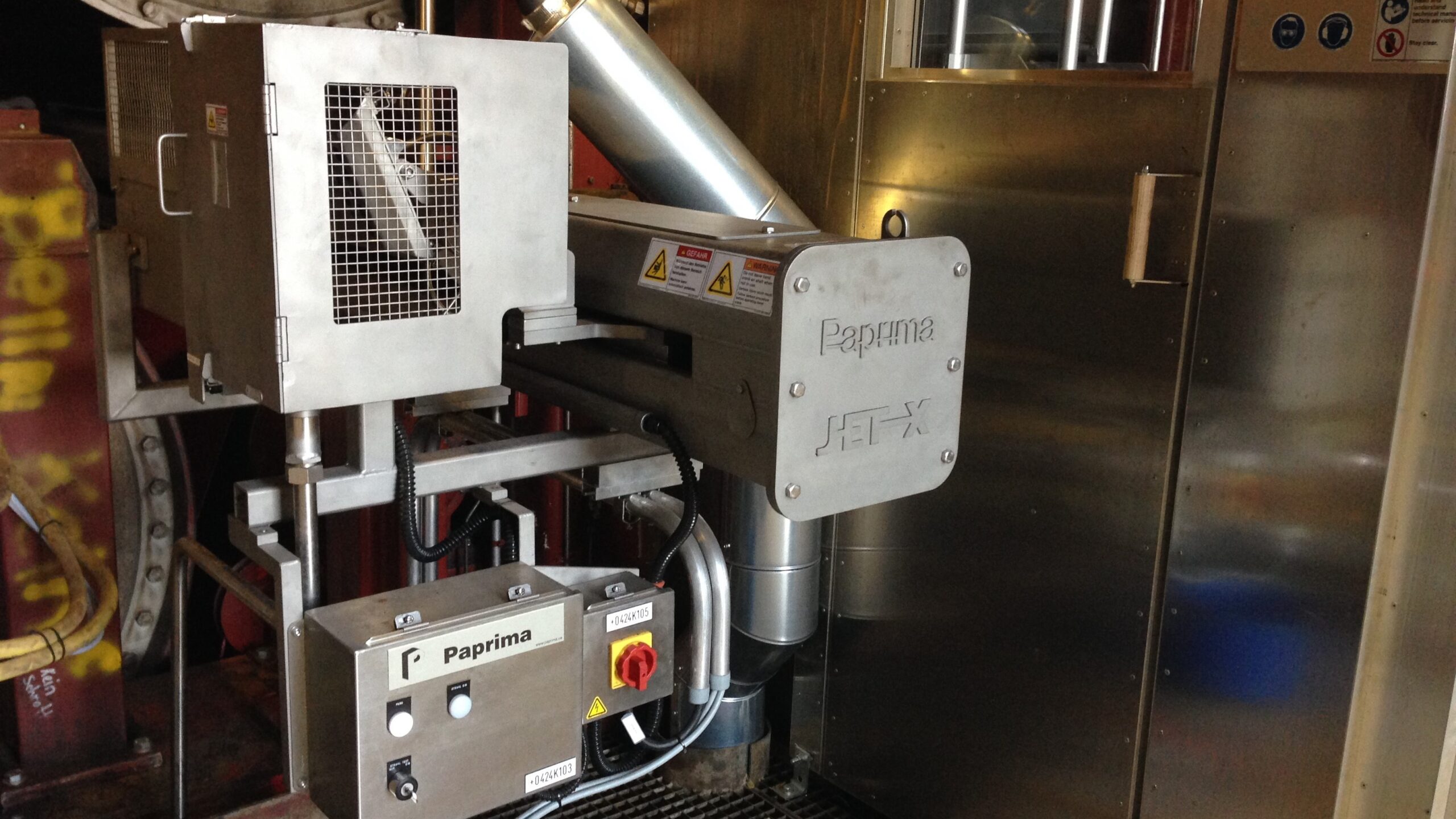

- The compact design fits most dryer pockets

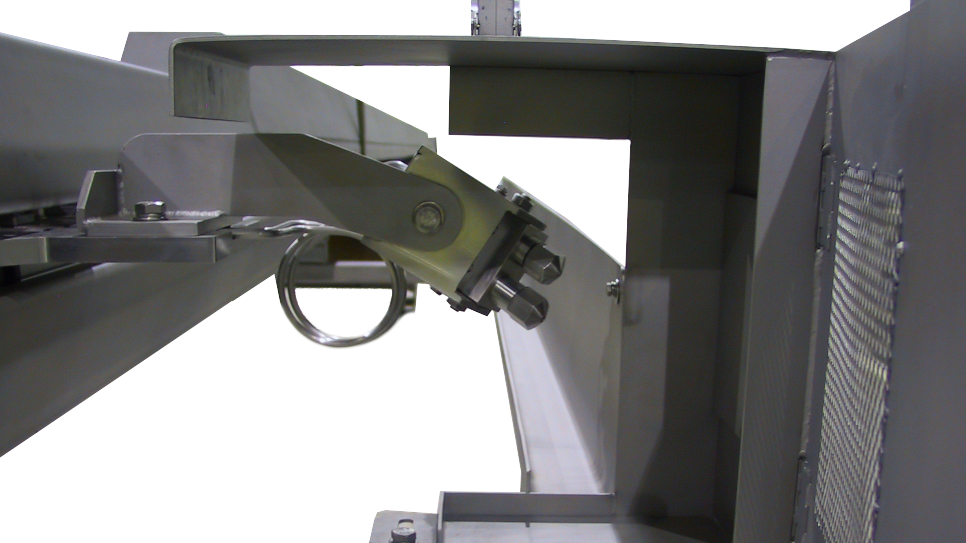

- Patented cutting head with an air ejector ensures positive sheet support

- Motor drive can be located on the tending or drive side

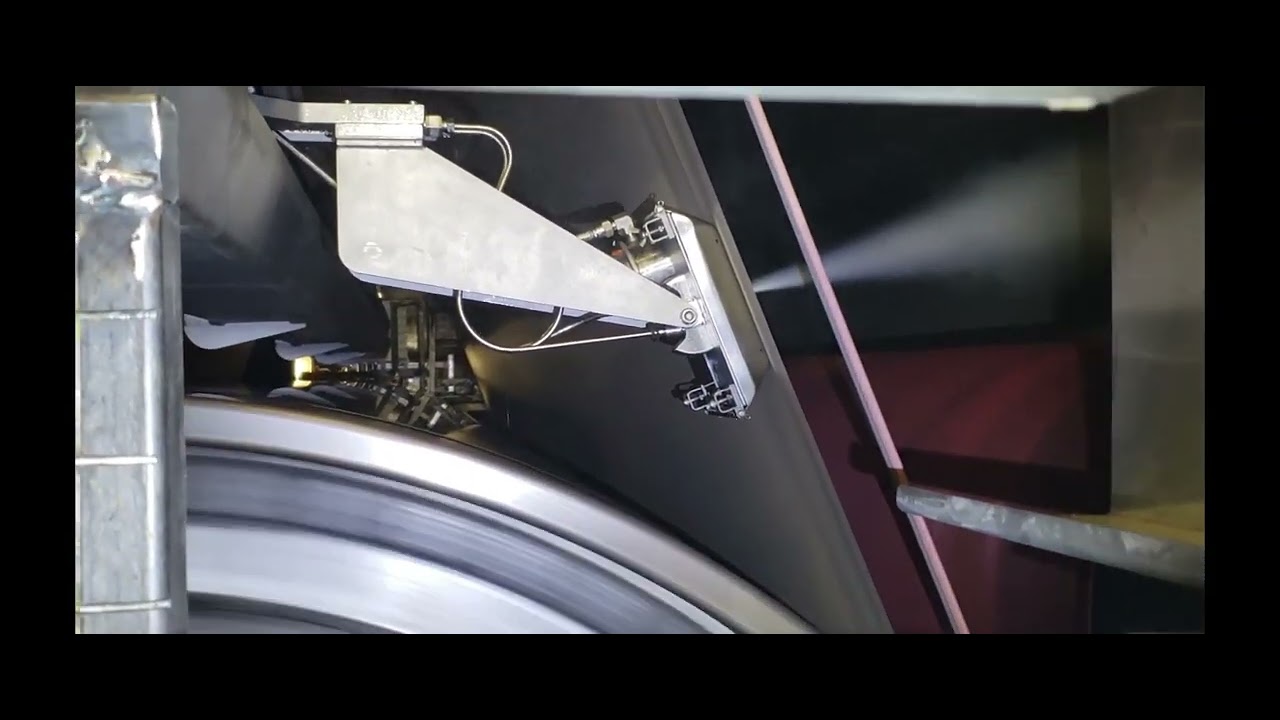

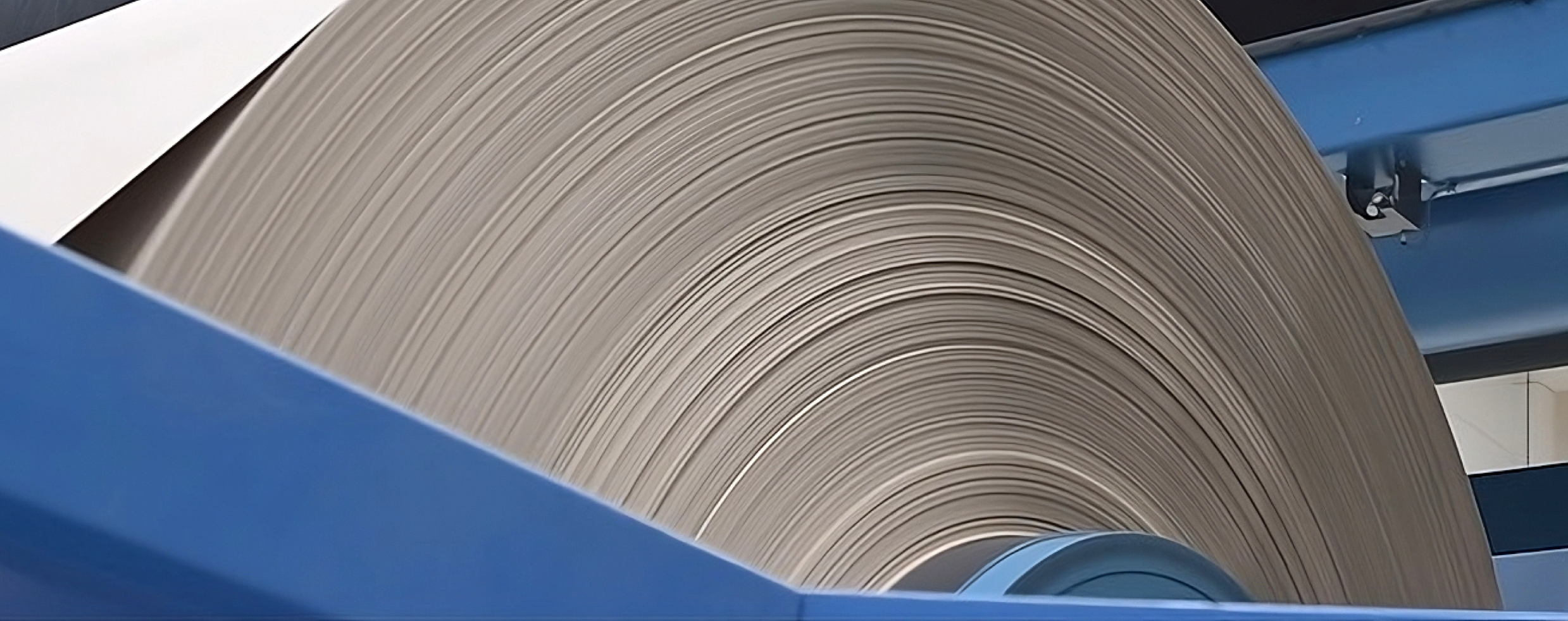

Cutting on the Last Top Dryer Cylinder

- The last top dryer provides consistent full-sheet support for reliable threading

- Keeps the dryer pockets open, and for ropeless threading

- Will not cause the sheet to break toward the upstream side

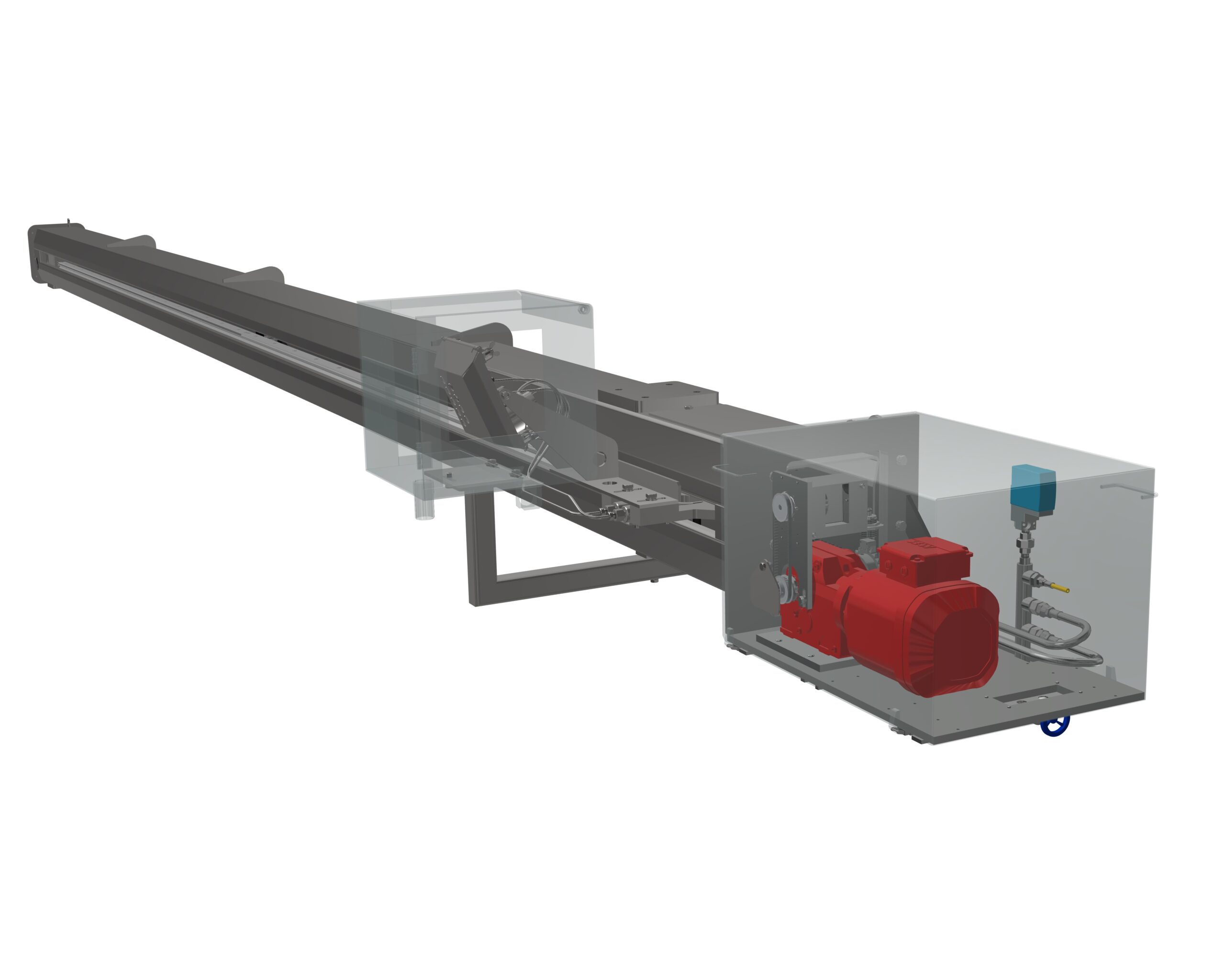

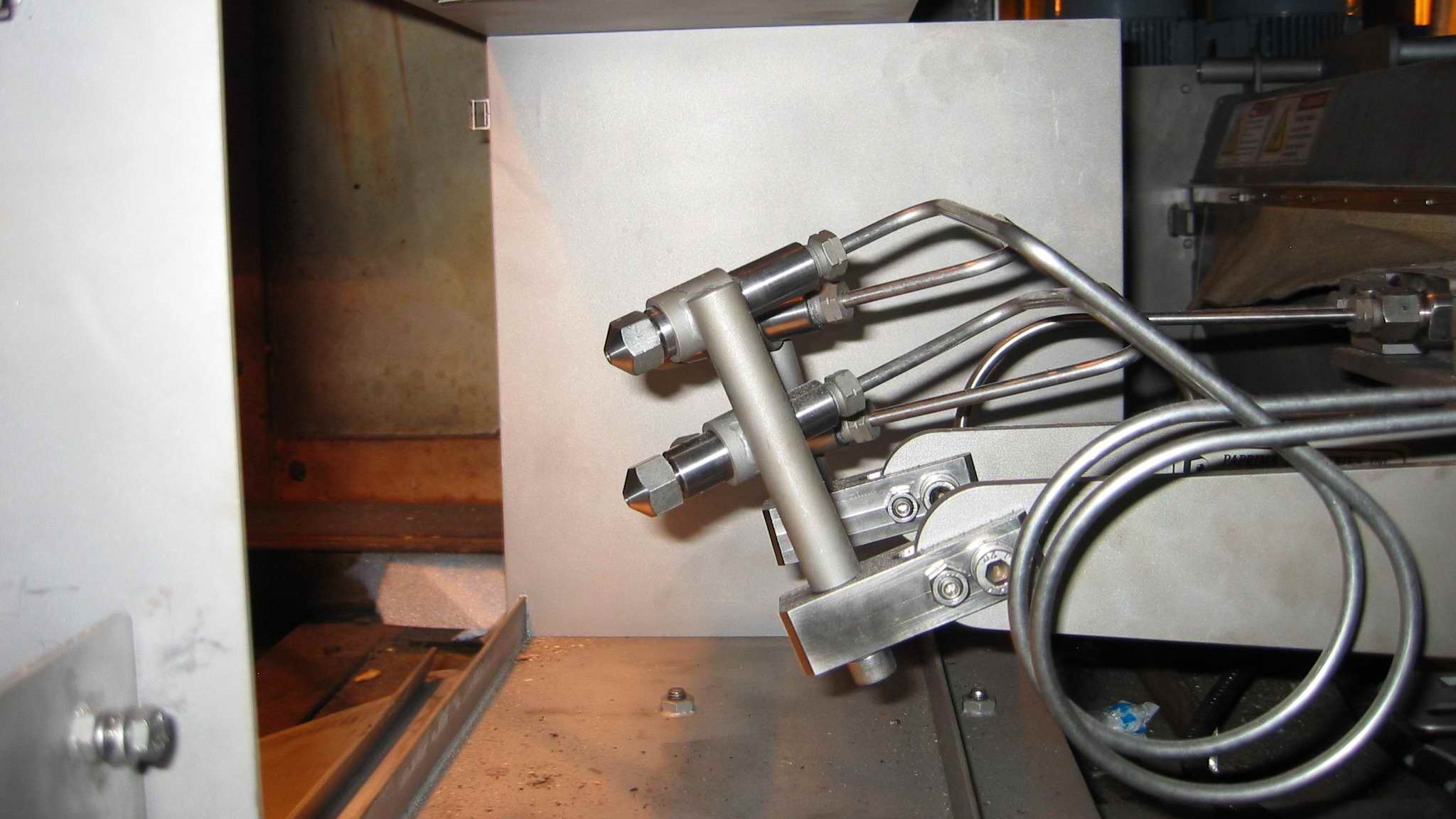

Features | Dry-End Tail Cutter

- Slide-out feature of a “beam within a beam” is standard

- Automatic tail cutting with pre-programmed tail widths

- Variable frequency drive with a cooled encoder for speed and positioning control

- High-pressure capability to cut all grades cleanly with minimal water

- Stainless steel construction

- Diamond cutting nozzles for reliable jets and long-life

- Back-up nozzle is standard

Advantages

- The tail cutter inner beam is designed to slide out, providing easy access to inner components for maintenance

- Provides consistent dust-free cutting

- Switch between nozzles instantly without any lock-out time required

- High-pressure hoses are air-cooled to ensure reliability and extend service life

- Multiple preset tail widths are easily operator-programmable

- Cutting is not affected by the speed, thickness, moisture content, tension, or oscillation of the sheet, thus allowing for a shorter wait time during startup and threading

- Drive components are enclosed to protect against contamination

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.

Open Draw

- The compact design will fit most dryer pockets

- Patented cutting head with an air ejector will ensure positive sheet support

- Motor drive can be located on the tending or drive side

Cutting on the Last Top Dryer Cylinder

- The last top dryer provides consistent full-sheet support for reliable threading

- Keeps the dryer pockets open

- Ideal for ropeless threading

- Will not cause the sheet to break toward the upstream side

Features | Water-Jet Dry-End Tail Cutter

- Slide-out feature of a “beam within a beam” is standard

- Automatic tail positioning with pre-programmed tail widths

- Variable frequency drive with a cooled encoder for speed and positioning control

- High-pressure capability to cut all grades cleanly with minimal water

- Stainless steel construction

- Diamond cutting nozzles for reliable jets and long-life

- Back-up nozzle is standard

Advantages

- The tail cutter inner beam is designed to slide out, consequently providing easy access to inner components for maintenance

- Provides consistent dust-free cutting

- Switch between nozzles instantly without any lock-out time required

- High-pressure hoses are air-cooled to ensure reliability and extend service life

- Multiple preset tail widths and positions are easily operator-programmable

- Cutting is not affected by the speed, thickness, moisture content, tension, or oscillation of the sheet, consequently allowing for a shorter wait time during startup and threading

- Drive components are enclosed to protect against contamination

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.