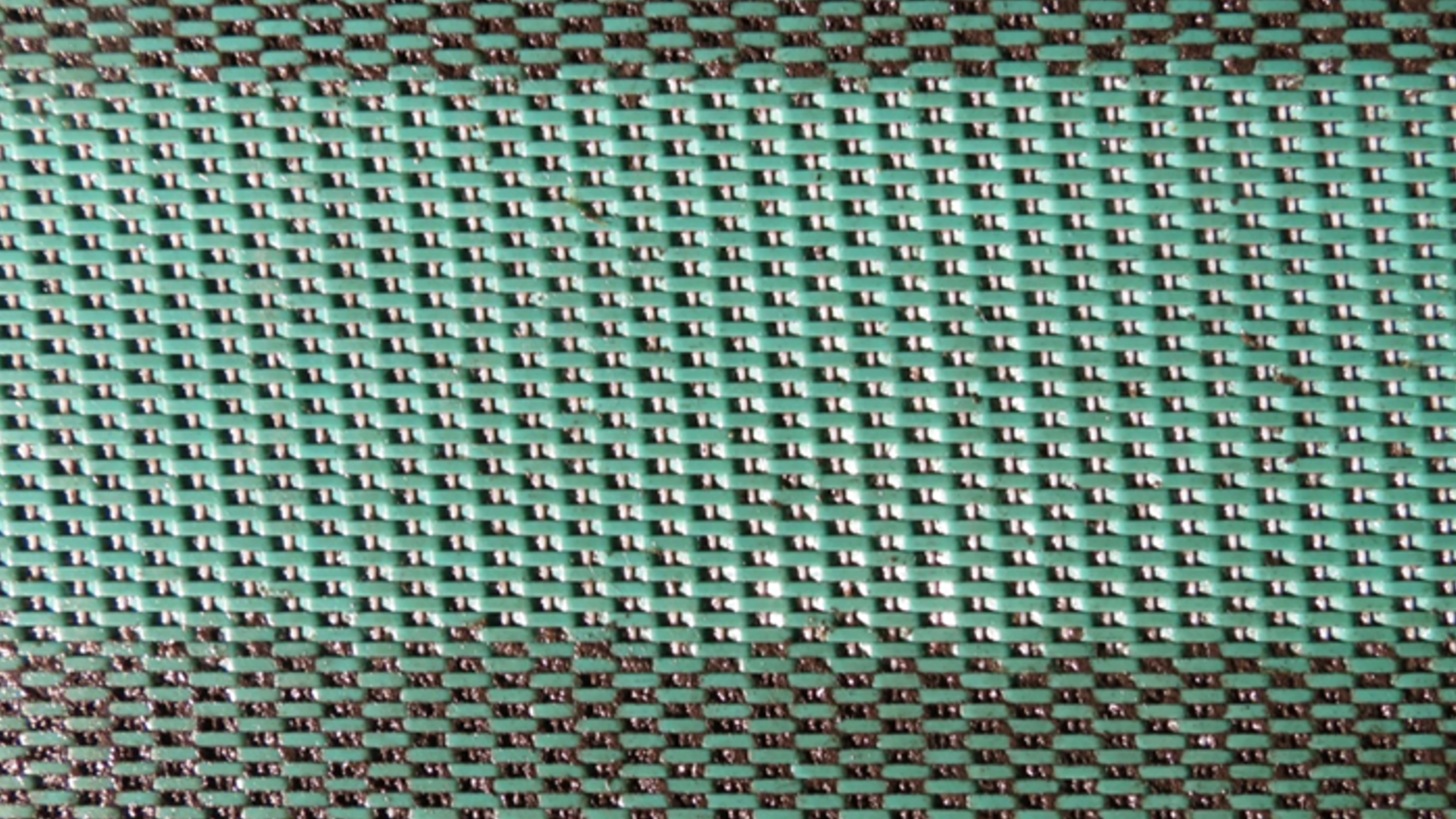

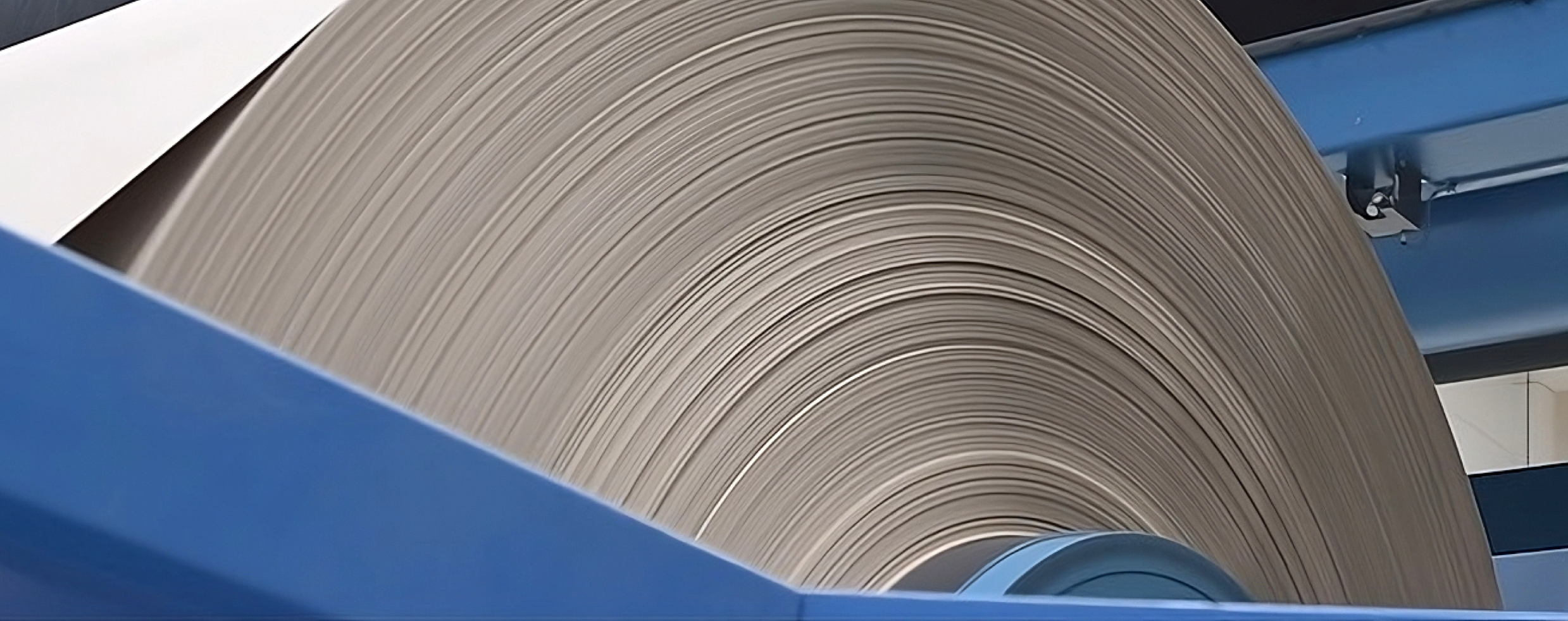

The dryer section of a paper machine relies heavily on steam, making efficient heat transfer essential for both energy savings and paper quality. Maintaining high permeability in the dryer fabric is therefore critical to achieving optimal performance.

As recycled content in pulp increases, managing stickies and plastic particles becomes more challenging. The dryer felt cleaner effectively addresses these issues, helping to maintain fabric condition, reduce energy costs, and deliver a more consistent, high-quality final product.

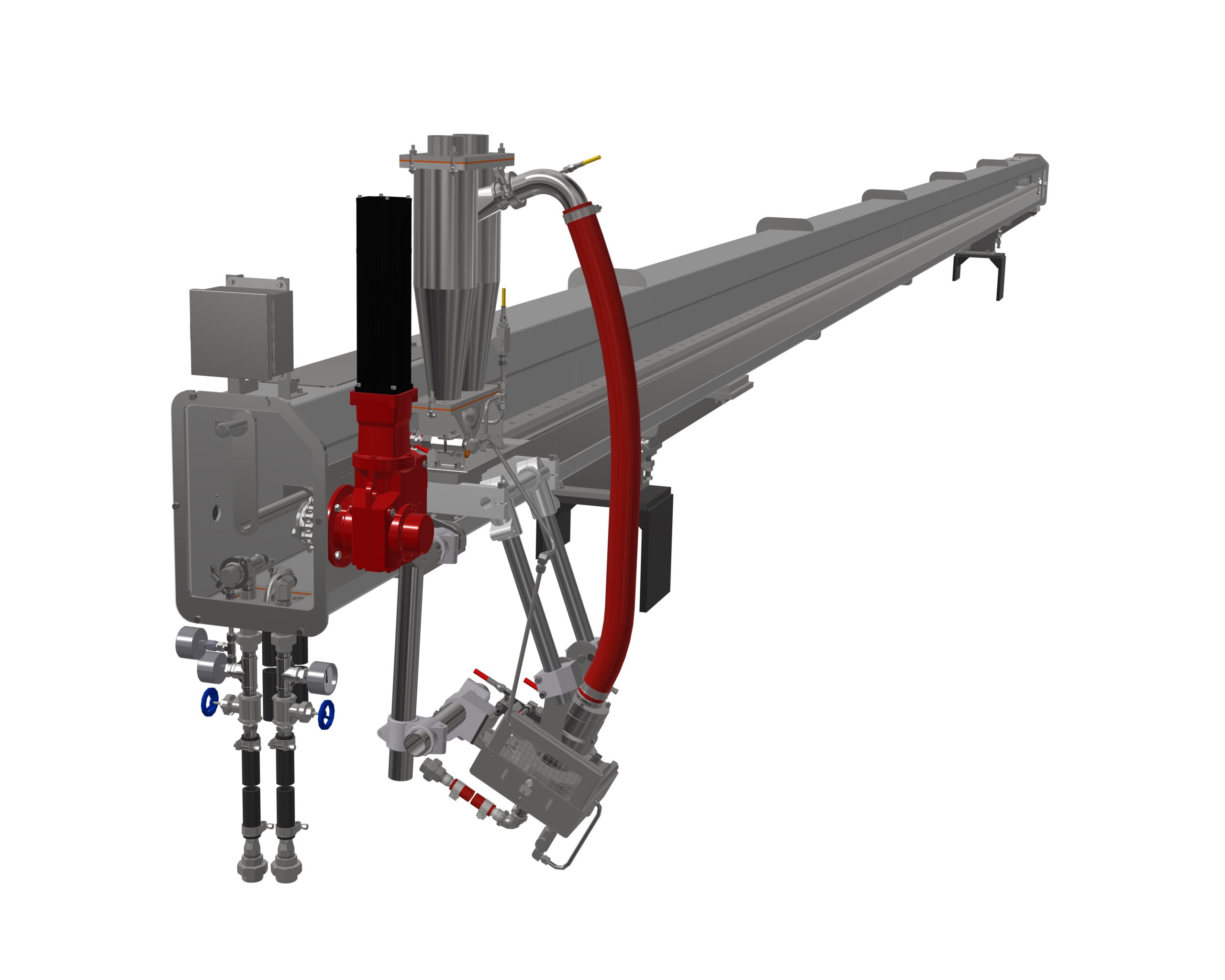

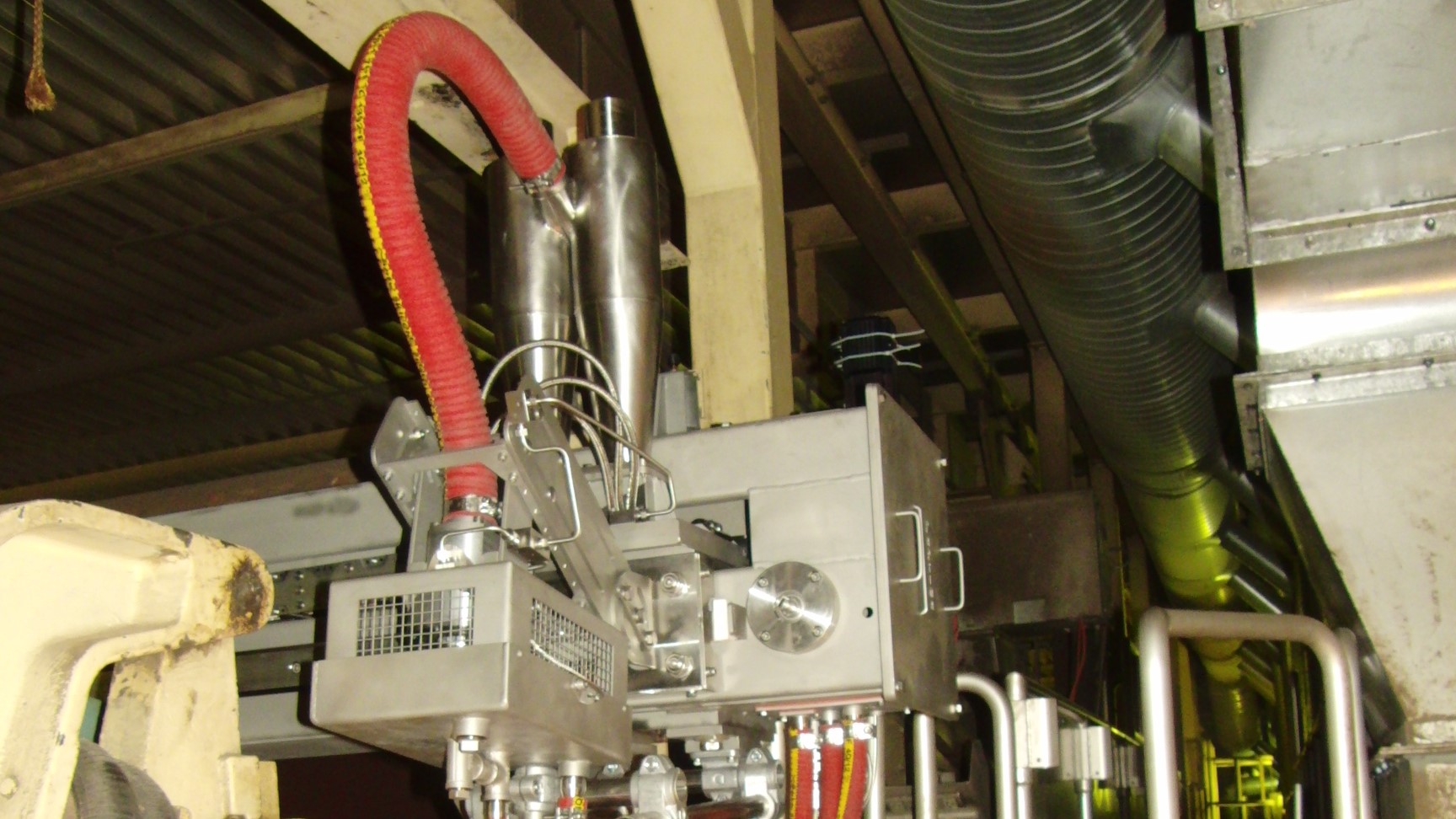

Features | Dryer Fabric Cleaner

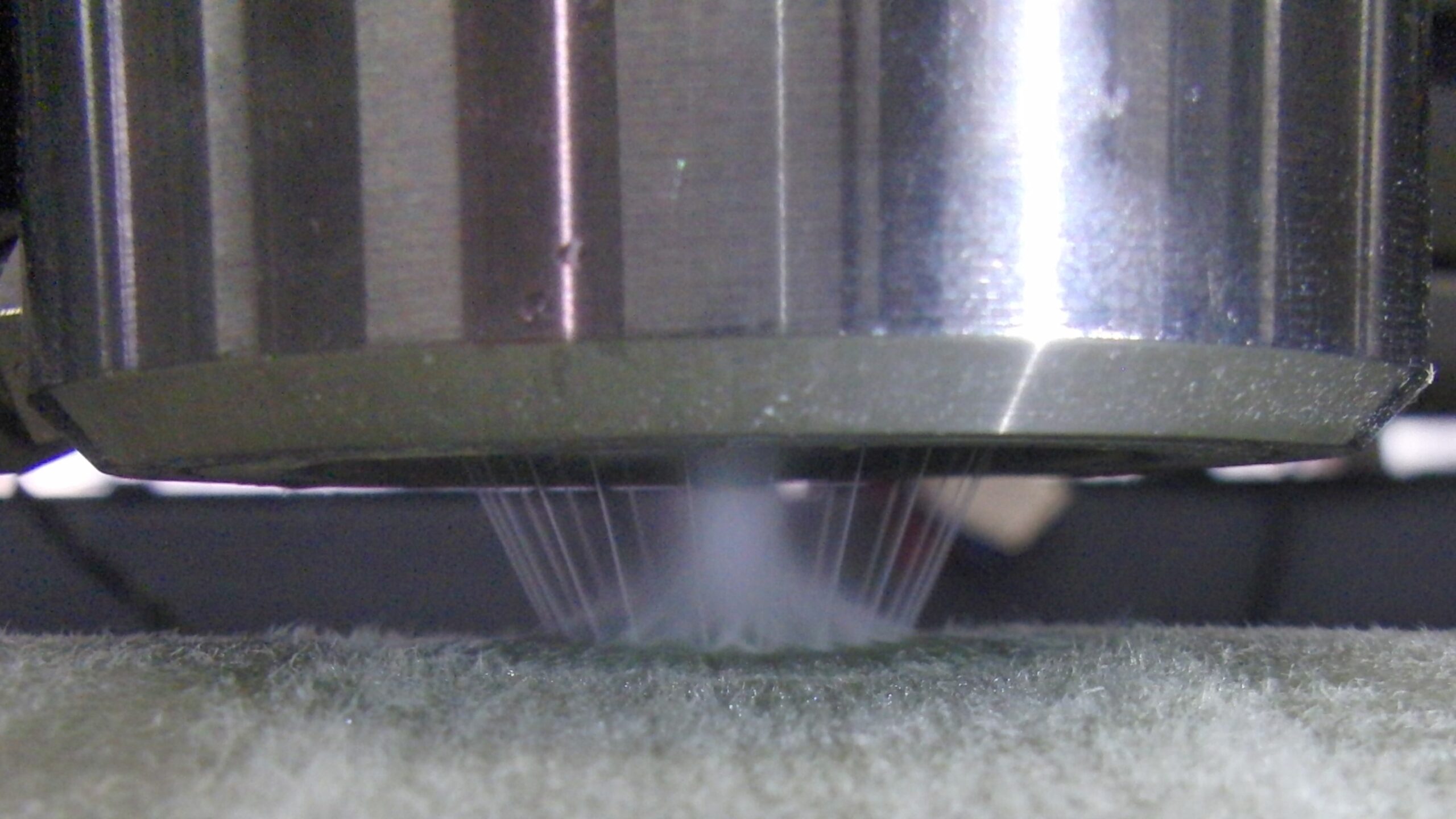

- The head uses a ring of medium-pressure water-jets to effectively loosen dirt, fibers and stickies

- Its patented system employs a non-contact positive air seal to capture water and contaminants from the fabric surface, combined with a carriage-mounted vortex ejector and cyclone separator for clog-free drainage.

- The cleaning pressure can be adjusted up to 6,500 PSI (450 bar) from the HMI

- The system features 6–12 nozzles per dryer fabric cleaner head, which can be configured for optimal cleaning results

- A head wash station enables automatic washing and scrubbing after every pass

Advantages | Dryer Fabric Cleaner

- Removes fabric surface buildup and stickies, thereby improving runnability and sheet quality

- It maintains a fabric permeability level of 90% of the as-measured permeability of a new fabric, significantly reducing drying energy consumption

- The overall installation cost is lower than most competitors

ROI

- Longer fabric lifespan

- Increases fabric permeability

- Lowers energy costs

- Reduces or eliminates cleaning chemicals, associated labour hours and machine downtime

- Improves sheet quality with fewer defects and sheet breaks

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.