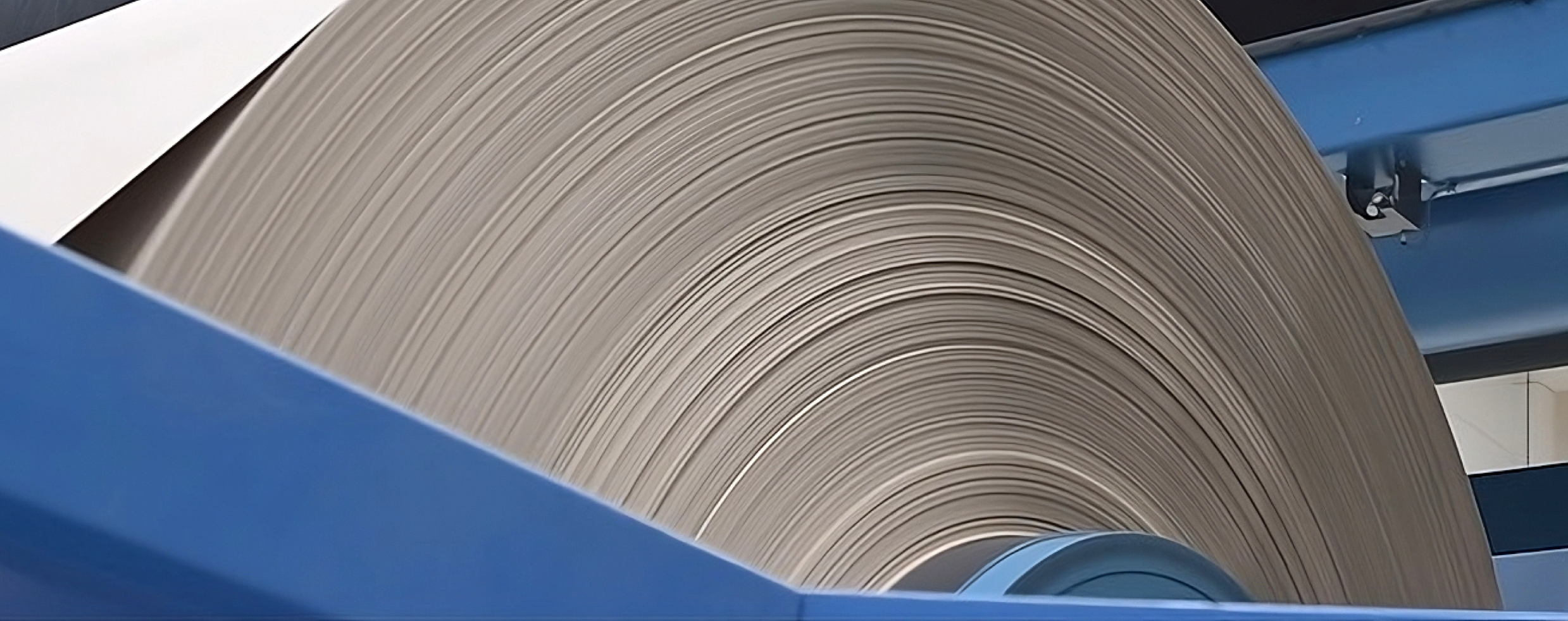

Our forming fabric cleaner is designed to significantly reduce mist and fibre buildup, improving cleanliness and operator safety in the wet-end area—particularly around save-alls, crosswalks, and stairs.

By eliminating the need for high-pressure oscillating shower pumps, the system offers considerable energy savings.

This innovative solution marks a major leap forward in forming wire and press felt cleaning, offering superior performance compared to traditional oscillating shower technology.

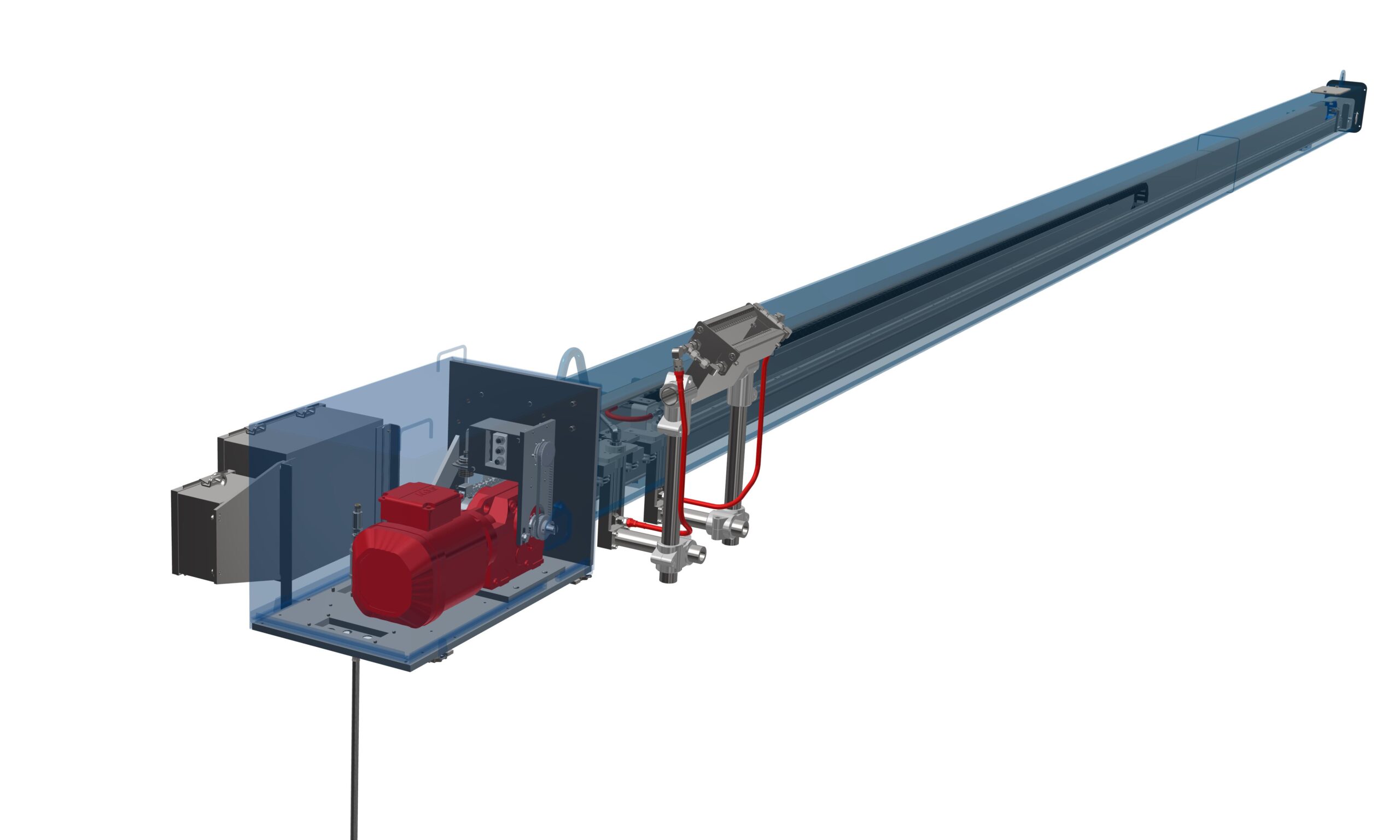

Features | Forming Fabric Cleaner

- The cleaning head features two rows of 20 medium-pressure water jets along with two rows of 20 air nozzles, which work together to effectively loosen dirt, fibers, and stickies while containing and eliminating them. The system utilizes a non-contact positive air seal to capture water and contaminants from the fabric surface, resulting in optimal fabric cleaning with minimal water consumption

- The cleaning pressure can be adjusted up to 2,200 PSI (151 bar) from the HMI

- The system uses approximately 7.5 lpm (2 gpm) of water per cleaning head, depending on grade, speed and fabric dimensions

- The cleaning head wash station enables automatic washing and scrubbing after every pass

Advantages | Forming Fabric Cleaner

- Removes fabric surface buildup and stickies, thereby improving runnability

- Reduces sheet breaks and defects in the forming sheet

- Achieves up to 95% water savings

- Helps reduce or eliminate the use of cleaning chemicals

- Mist-free operation

ROI

- Longer fabric lifespan

- Increases fabric permeability

- Reduces energy costs

- Decreases machine downtime

- Water consumption is lowered by eliminating the need for high-pressure showers

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.