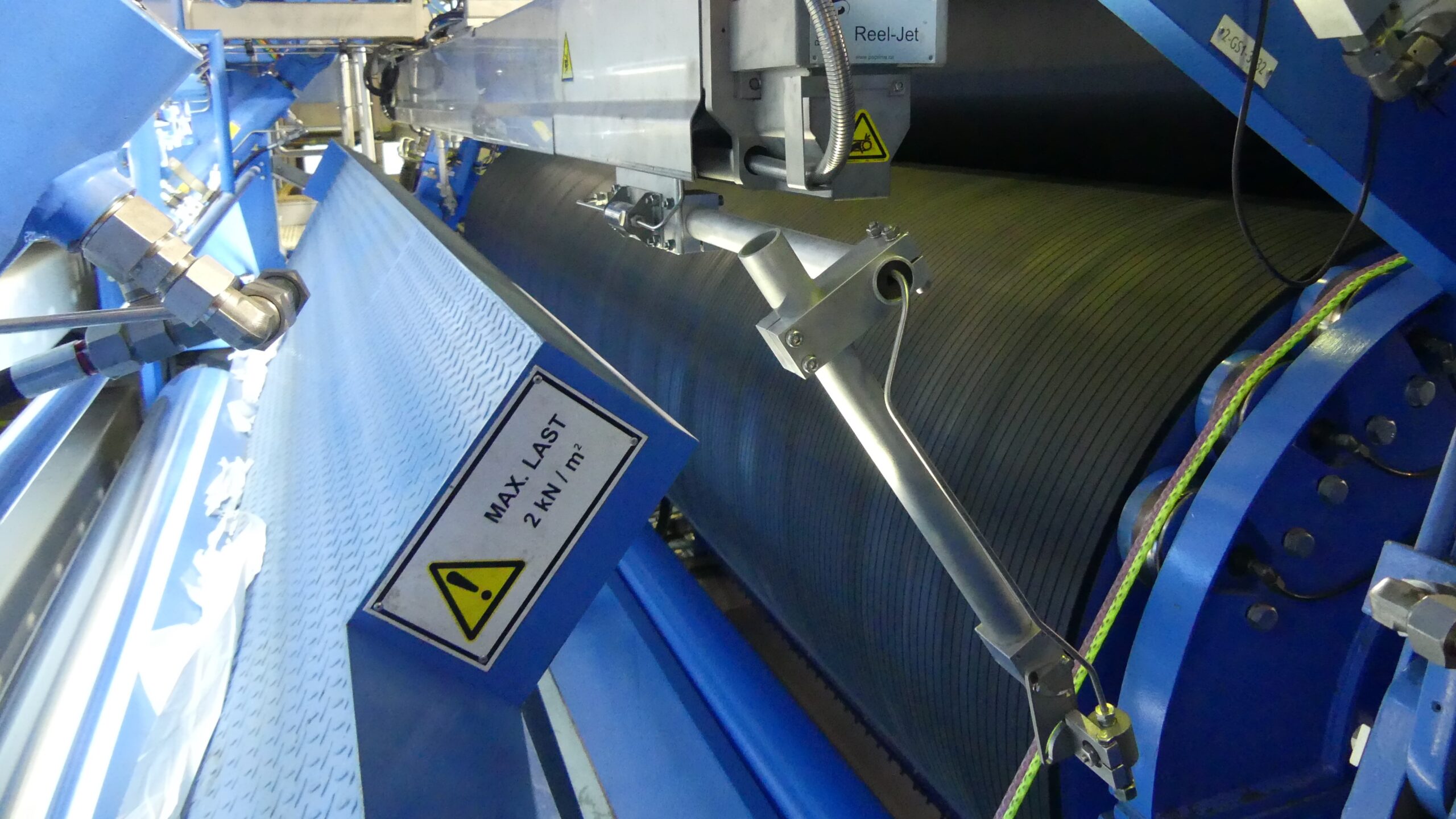

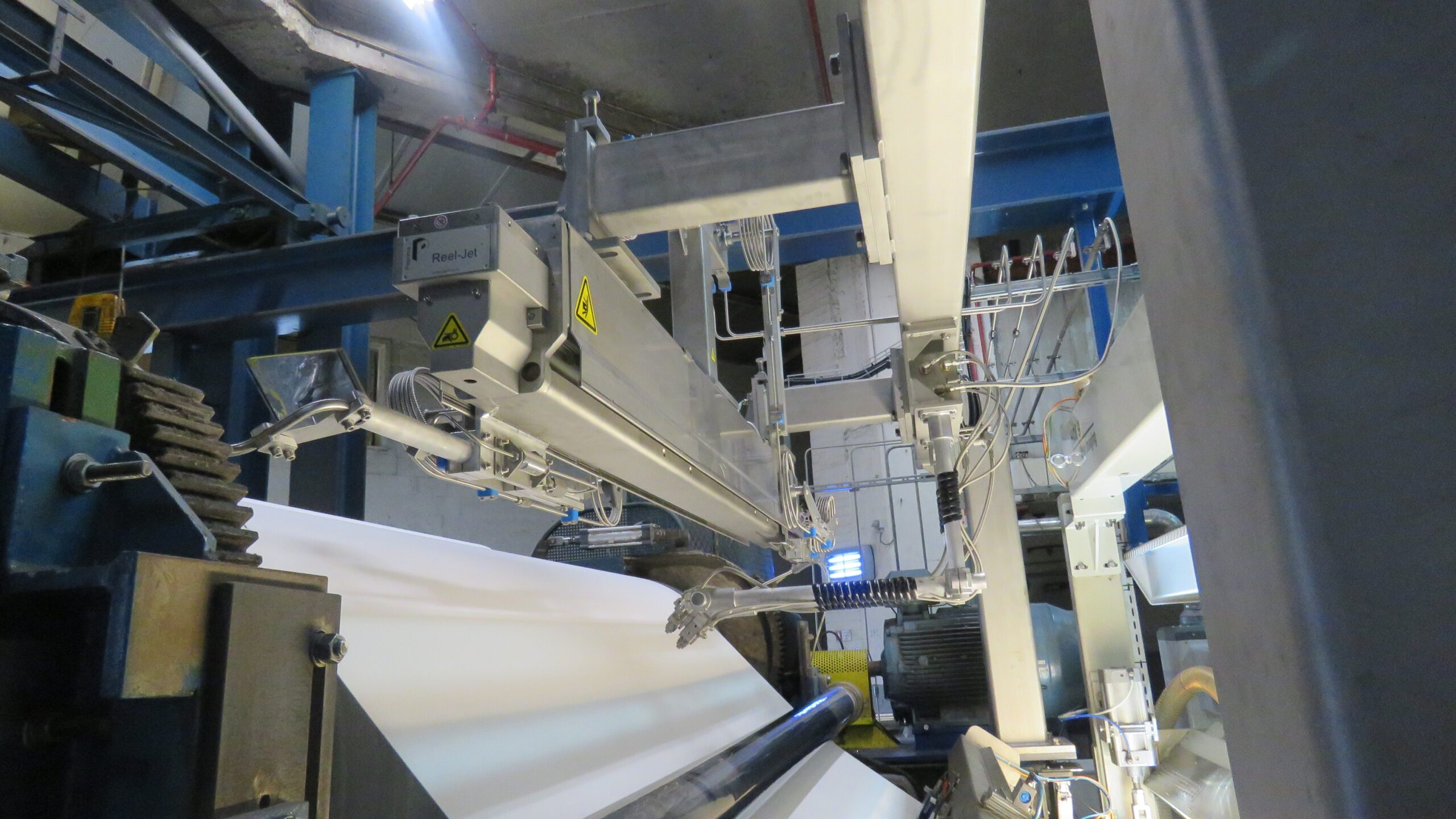

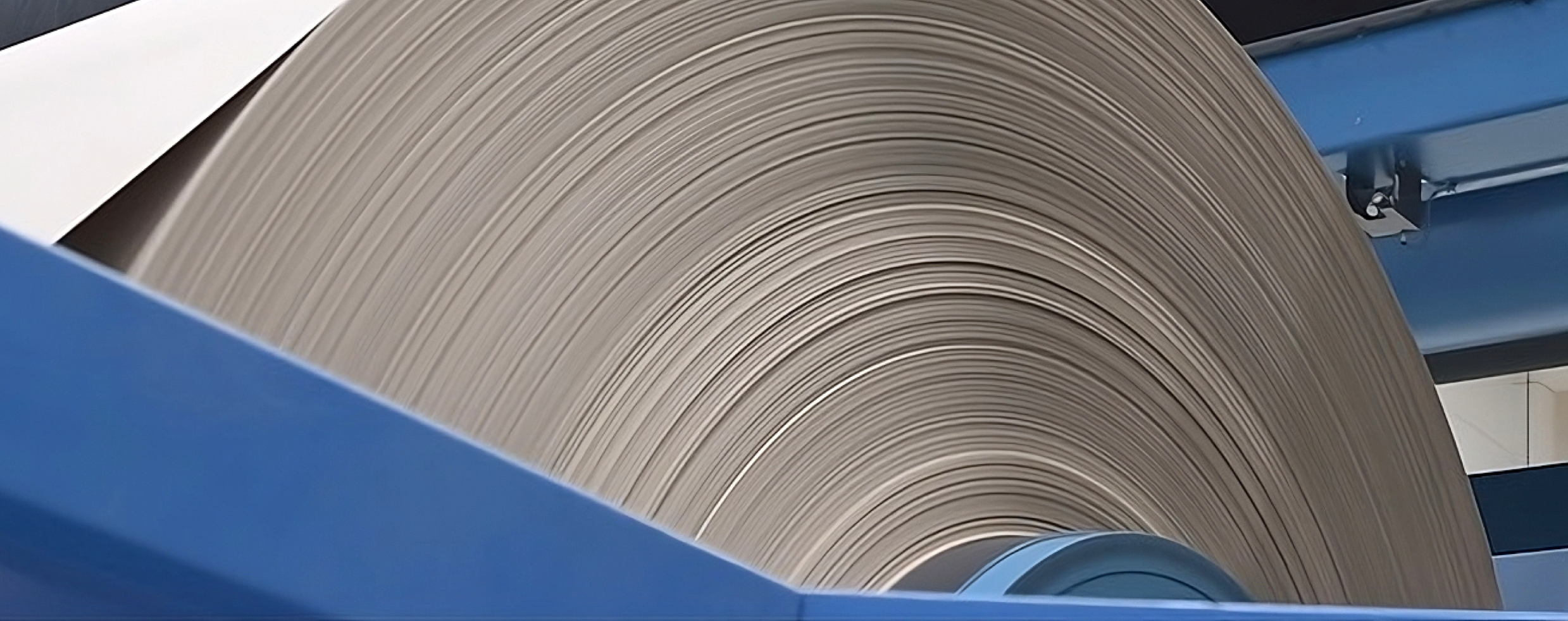

Given the technical demands, water-jet turn-up technologies deliver a high degree of reliability. Reel change systems must start and finish the cutting process within just a few hundred milliseconds. The process begins with the initial chevron-shaped tip adhering cleanly to the spool. As the symmetrically widening web winds around the spool, subsequent layers are distributed evenly without folds until the full web width is rolled up.

Throughout the entire reel change process, there is no mechanical shock, dusting, or undesirable paper loss on the spool. The high-pressure water-jet provides enough energy to reliably cut any basis weight, passing through a diamond nozzle to form a laminar, cohesive jet at ultrasonic speed. At the same time, the amount of water sprayed onto the pope roller is minimal, leaving no trace or surface damage. Unlike tape turn-up systems, water-jet technologies avoid tape imprints, ensuring a clean, precise reel change every time.

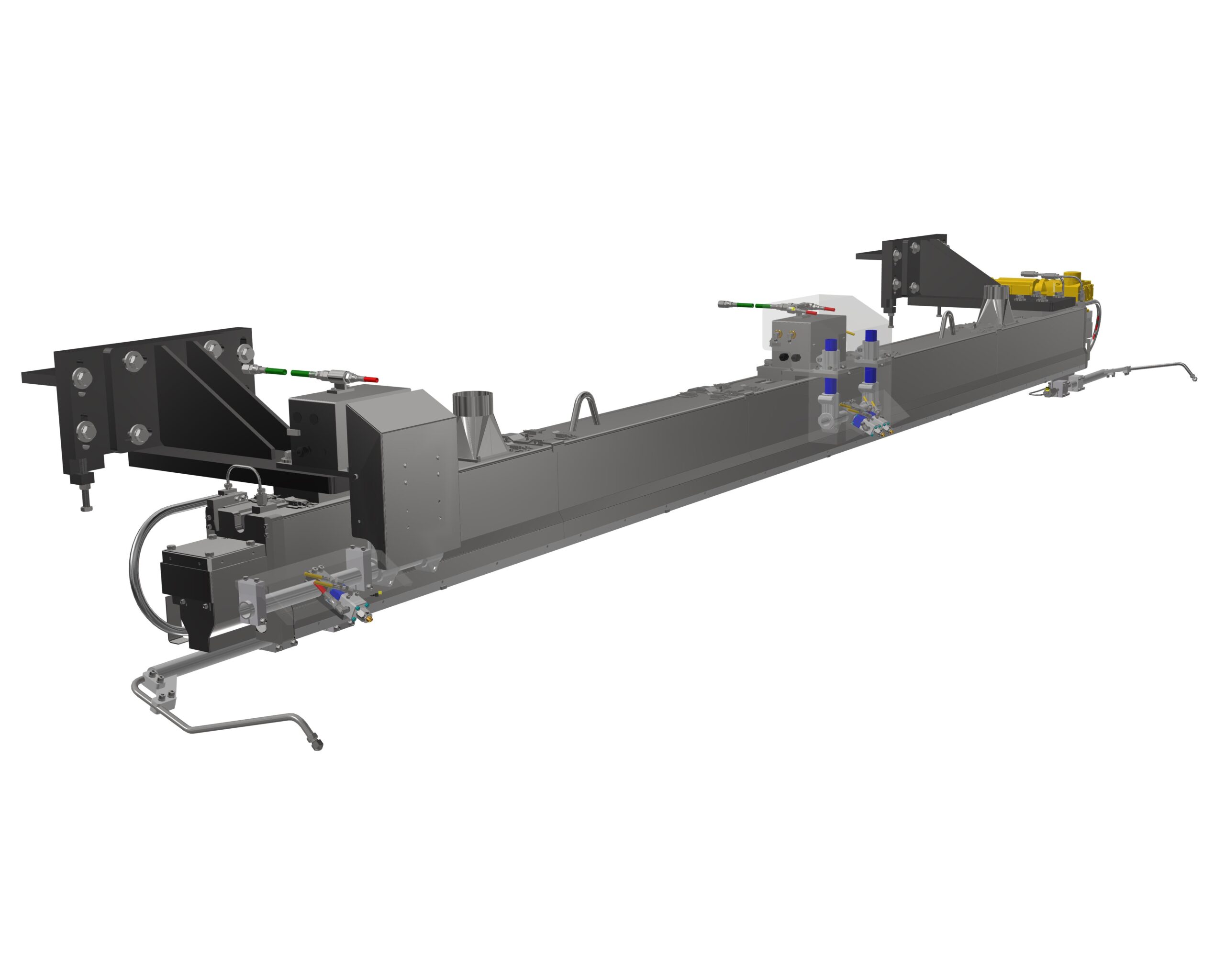

Features | Water-Jet Turn-up System

- Turn-up sealants are water soluble and repulpable, making them widely accepted for consumer products

- A user-friendly operator interface with multiple configuration selections

- Full-opening side panels allow easy service access

- Stainless steel construction ensures durability

- Diamond cutting nozzles provide reliable jets and long service life, enhancing overall performance

Advantages | Water-Jet Turn-up System

- Compared to a tape turnup system, a symmetrical cutting profile significantly reduces wrinkling, thereby minimizing spool core losses

- Easy service access simplifies maintenance, reducing the time required for troubleshooting and repairs.

- Significantly minimize loose or flying paper from the parent roll

ROI

- Low core loss, typically less than 100 linear meters

- Turn-up efficiency shall equal or exceed 98% for paper and 95% for hygiene grades

- Increased turn-up efficiency can lead to production savings of 0.5% to 2%, which translates into a payback period of just 6 to 12 months.

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.