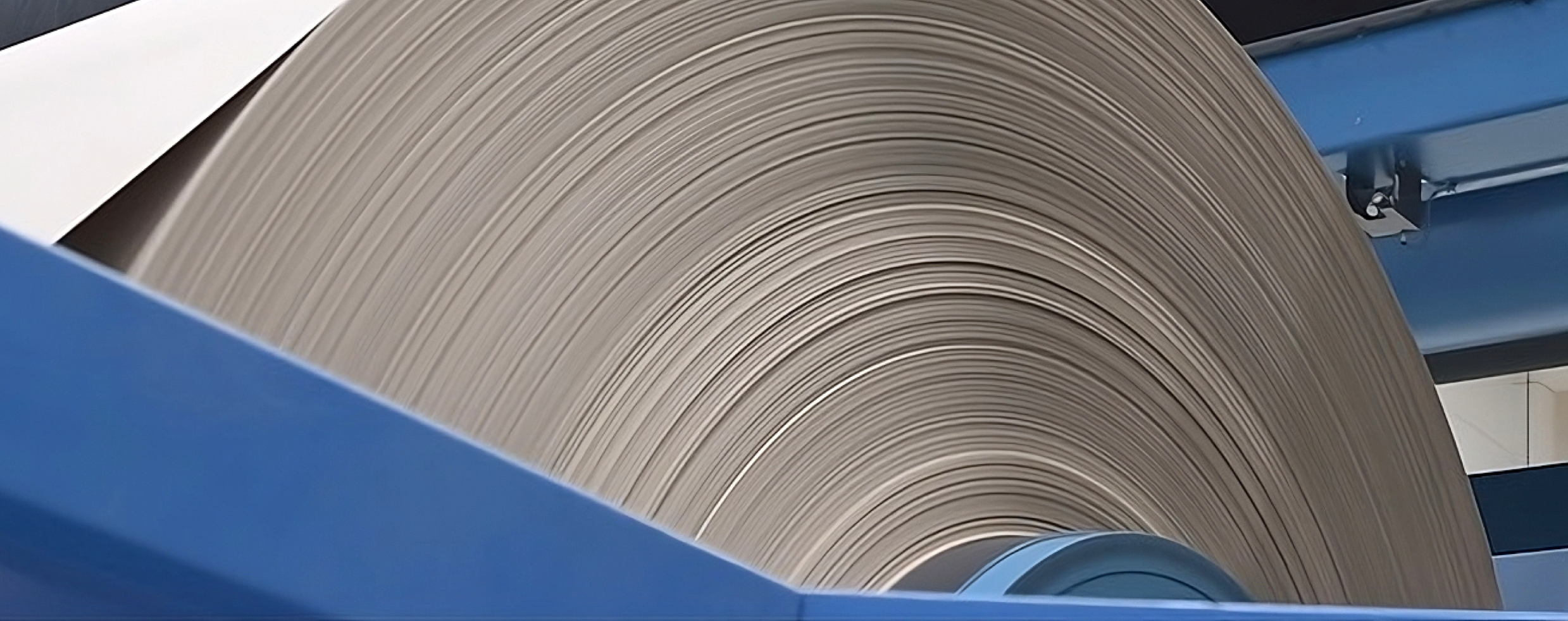

When manufacturing tissue papers, the traditional method of cutting the parent roll into smaller widths with an offline re-winder can limit the potential to increase the speed and efficiency of the tissue machine. The reel spools may not return to the machine quickly enough, leading to unnecessary costs from extra handling and cleaning of spools or the disposal of butt rolls, which requires additional staff.

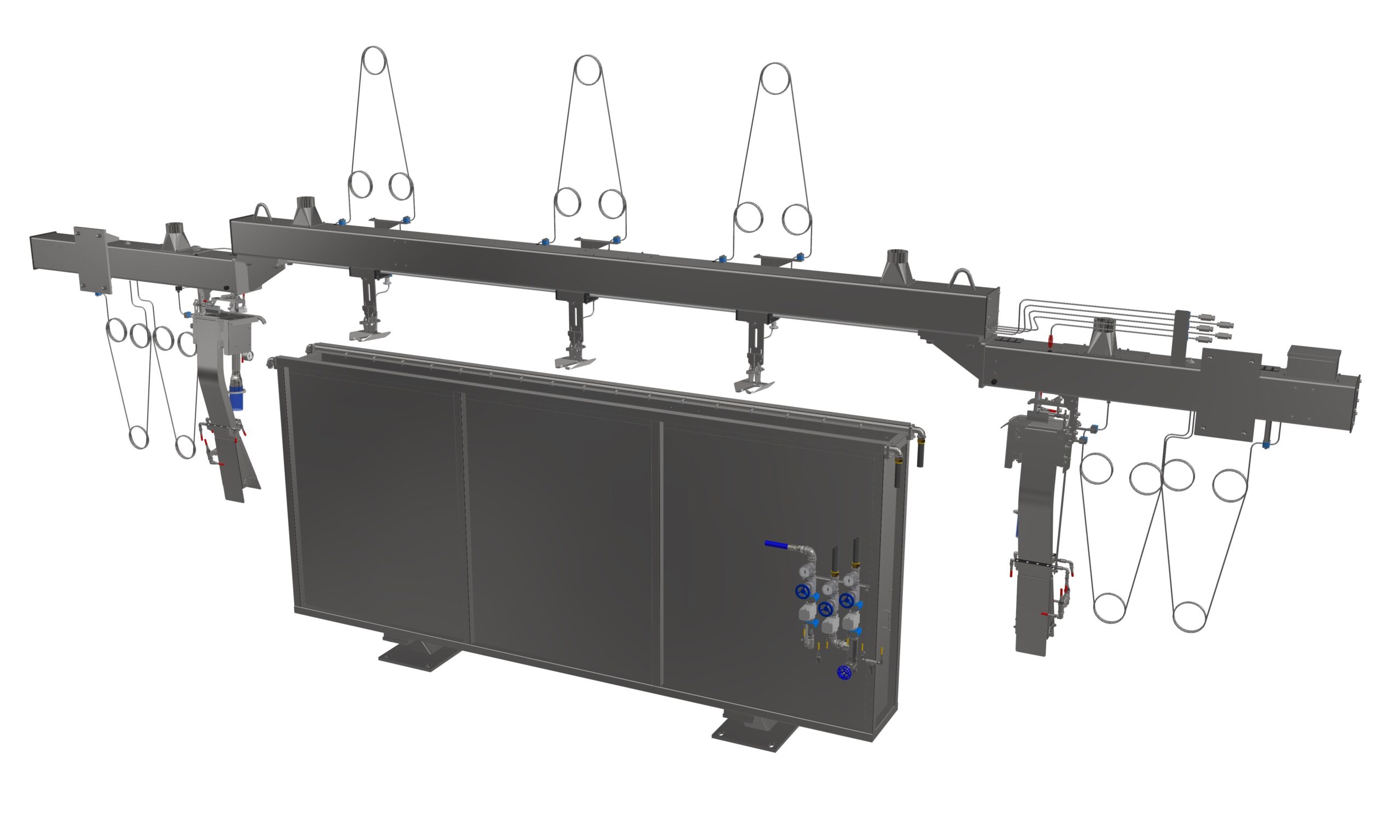

Each Trim-Jet™ H solution can be customized to include water-jet tissue edge-trimming and/or single or multiple slitting of tissue grades needed for all your production sets. When automated, each tissue slit and tissue trim station will precisely and repeatedly position each roll width as configured in the user-friendly interface. Each created production set can be saved and recalled, easing production changeovers and minimizing downtime for adjustments.

Features | Tissue Slitting & Edge-Trimming

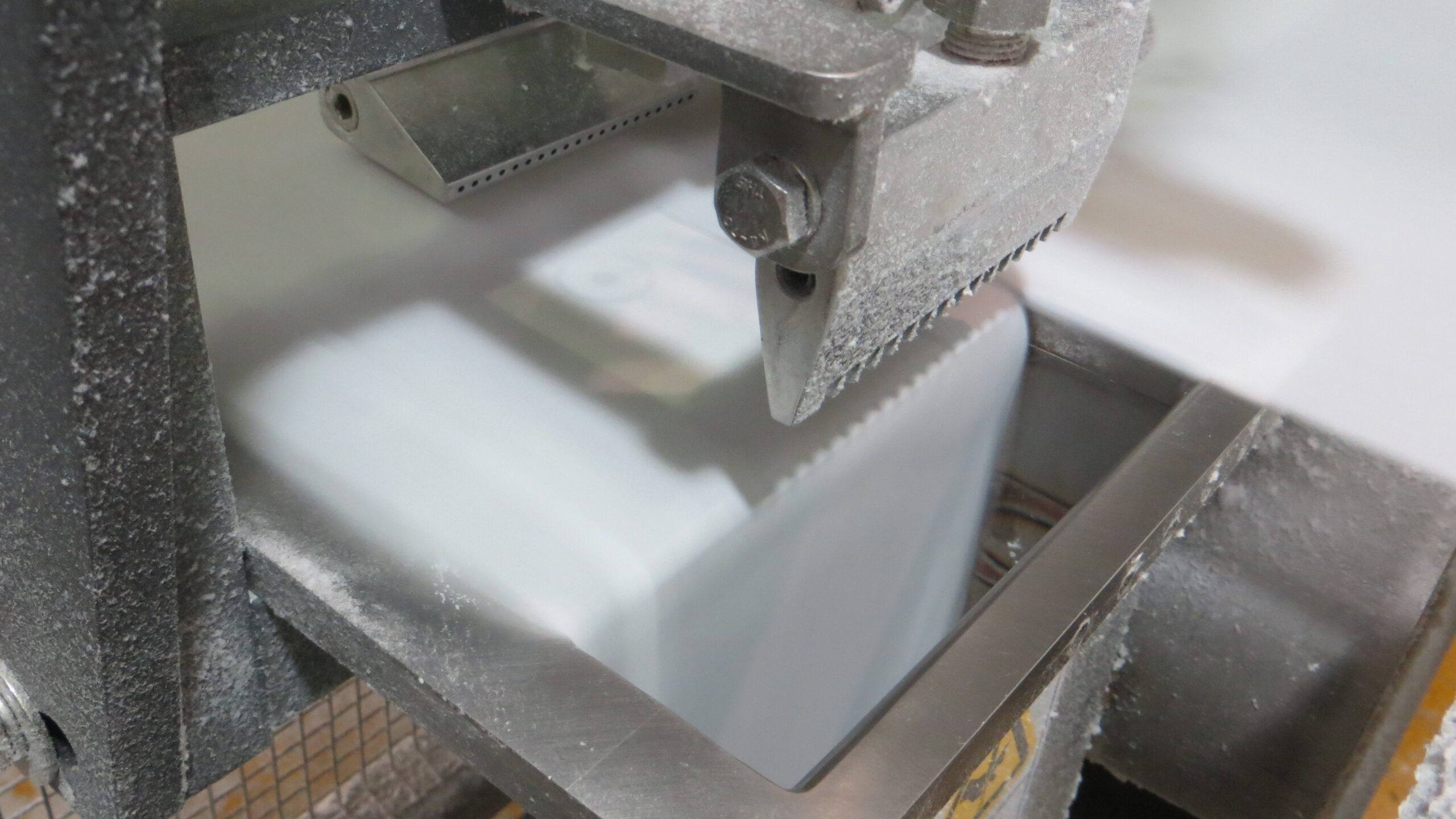

- Cut tissue edge trims as small as 20mm (0.75”) and up to 150mm (6”) or higher

- The system can eliminate the need to wind butt rolls by returning the unwanted product directly to the pulper

- Can handle and convey trims using compressed air or a blower fan

- Stainless steel construction

- Diamond cutting nozzles for reliable jets and long-life

Advantages | Tissue Slitting & Edge-Trimming

- Provides consistent airborne dust-free slitting

- Eliminates tissue sheet edge defects that may lead to sheet breaks at the reel or offline winder/slitter

- Can effectively trim an oscillating sheet to produce a high-quality fixed-edge

ROI

- The system reduces or eliminates the need for offline slitting converting processes

- It reduces manpower requirements

- Increased machine speed

- Sheet breaks caused by cracked edges are minimized

- Butt roll handling and bottom spool broke cleaning are eliminated

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.