Features | Wet-End Tail Cutter

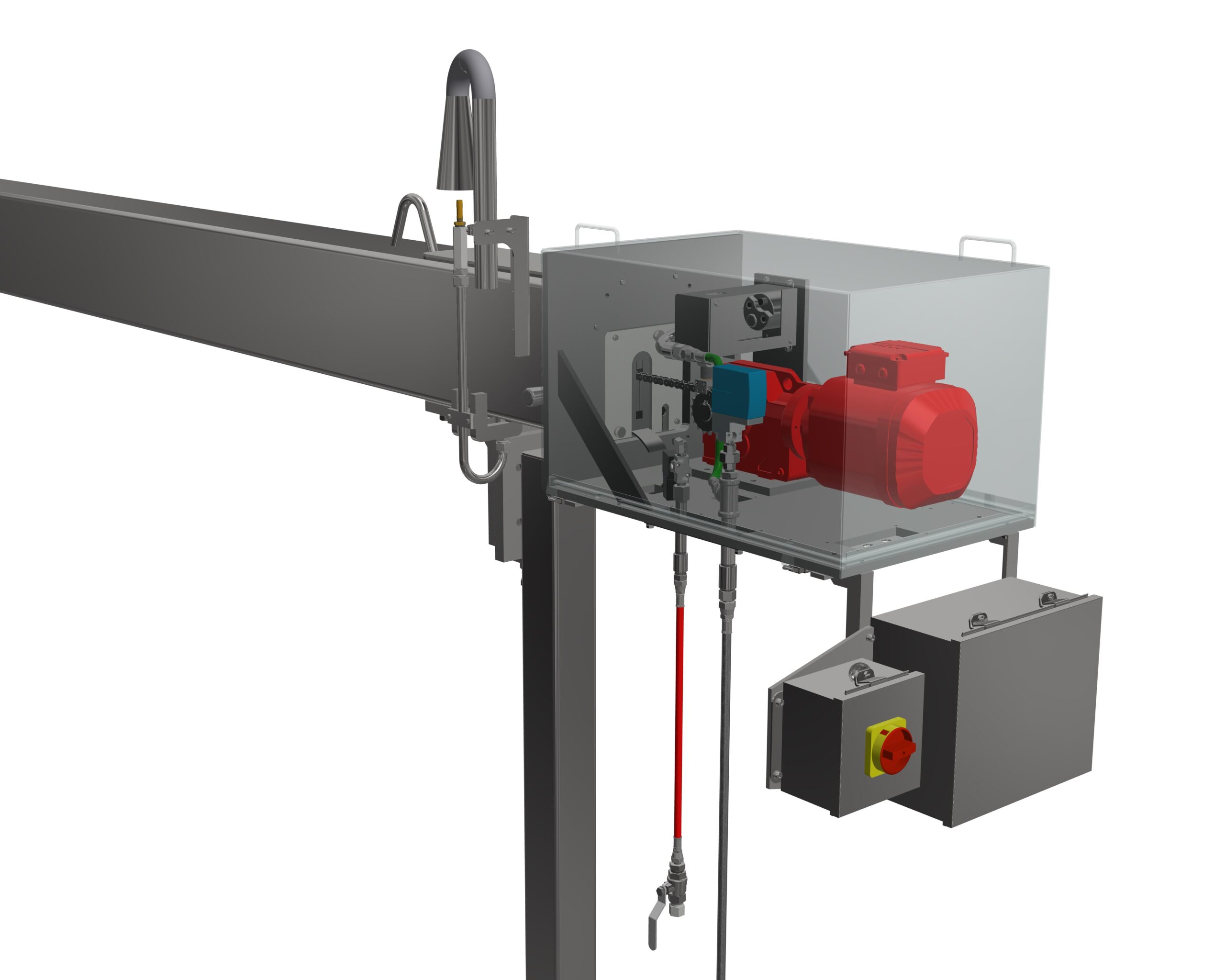

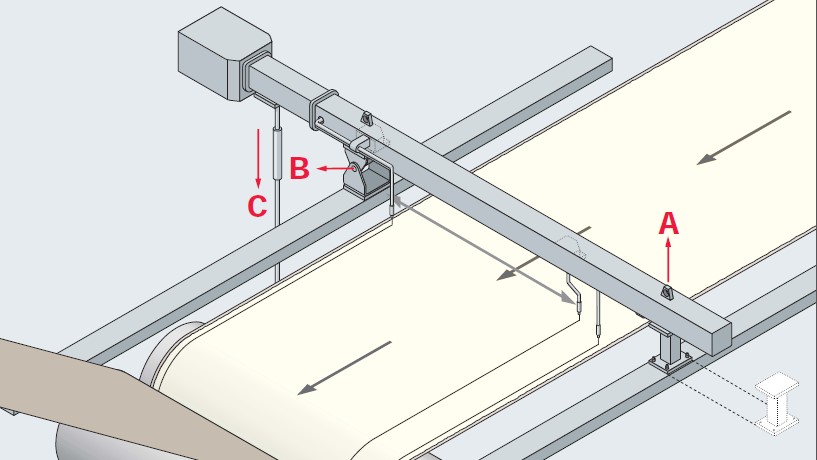

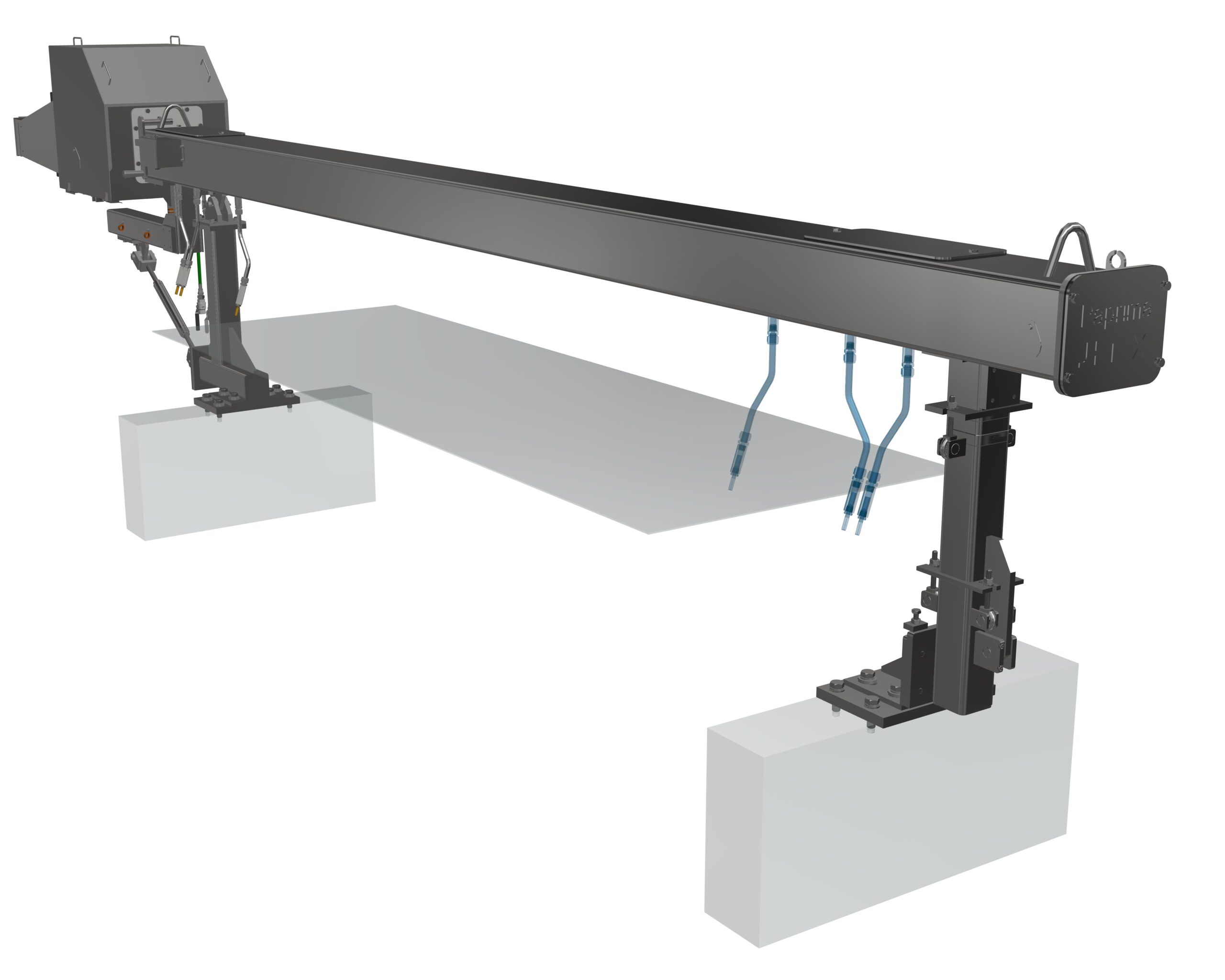

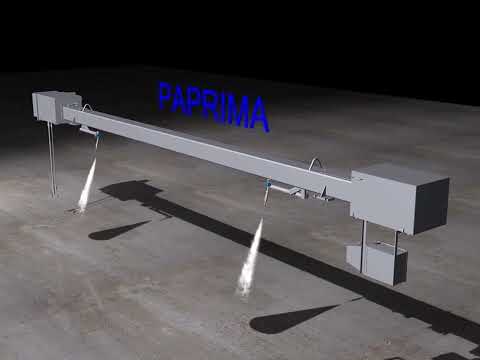

- Slide-out feature of a “beam within a beam” is standard

- Variable frequency drive with a cooled encoder for speed and positioning control

- Stainless steel construction DIN 1.4404 (AISI 316L)

- Compact beam with fixed lifting hooks

- Motor drive can be located on the tending or drive side

Advantages

- The tail cutter inner beam is designed to slide out, providing easy access to inner components for maintenance

- Drive components are enclosed to prevent dirt and water infiltration

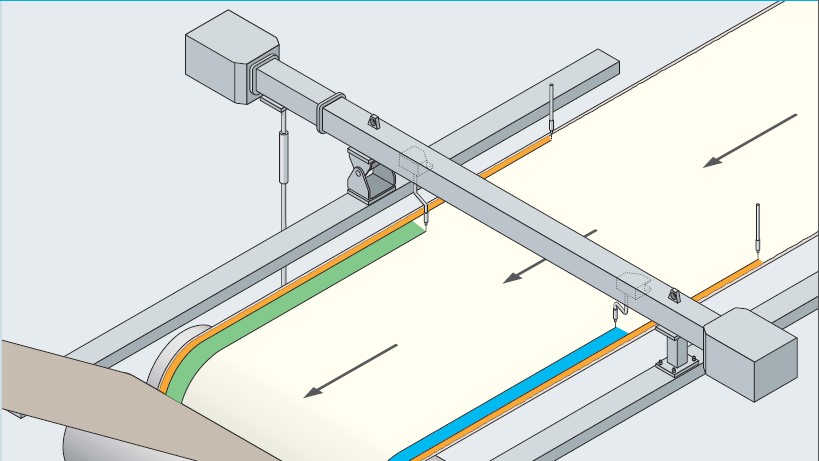

- Multiple preset tail widths are easily operator-programmable

- Can be operated by remote HMI or operator panel push buttons

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.

Features | Wet-End Tail Cutter

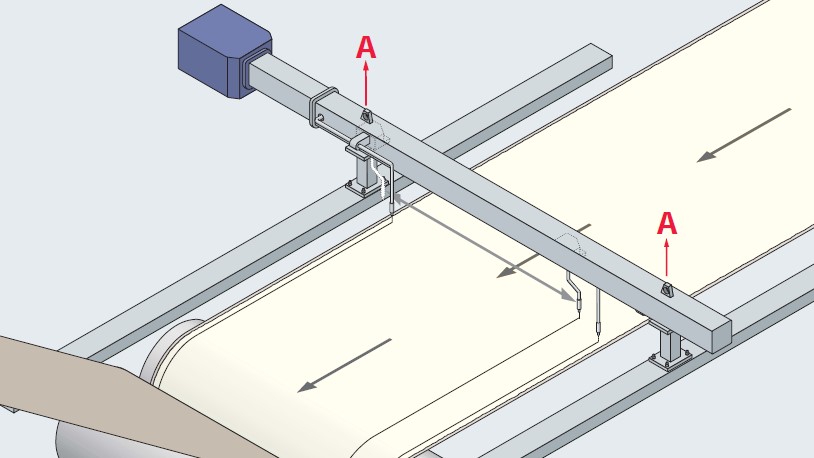

- Slide-out feature of a “beam within a beam” is standard

- Two variable frequency drives with a cooled encoder for speed and positioning control

- Stainless steel construction DIN 1.4404 (AISI 316L)

- Compact beam with fixed lifting hooks

- Motor drives can be located on the tending or drive side

Advantages

- The tail cutter inner beam is designed to slide out, providing easy access to inner components for maintenance

- Drive components are enclosed to prevent dirt and water infiltration

- Multiple preset tail widths, positions, and trim widths are easily operator-programmable

- Adjusting the trim positioning can reduce energy and handling costs by removing trim at the wet-end instead of after the reel when changes in paper grades and basis weights are common

- Can be operated by remote HMI

Let's Connect and Discuss Your Needs!

Get in touch to learn more about our solutions and how we can contribute to realizing your objectives.