Advantages

Ultra-high pressure (UHP) water-jet edge-trimming offers:

- dust free cutting

- faster production

- reduced maintenance

- improved safety compared to saw blade cutters

- no saw blades to sharpen

- cuts narrower trim (product dependent)

- trims an oscillating web (product dependent)

Water-jet nozzles are typically running kerf loss of 0.003” to 0.015” (0.076 mm to 0.381 mm) – an 85%-95% saving on cutting loss. This is an immediate saving and increases your yield

Customers immediately notice the reduction in dirt and dust build up in the cutting area, which benefits the employees with a cleaner and healthier work environment. No vacuum or dust bag maintenance is required and helps in the reduction of fire hazards.

Paprima has a dedicated pilot facility that can run test cuts as a trial to confirm speed and edge quality

Features

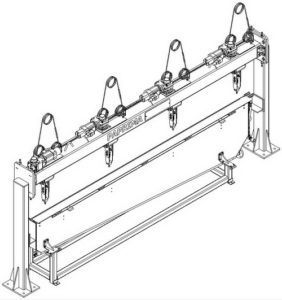

The Jet-Xtm Trimmer is an automatically adjusted water-jet edge-trimmer, usually equipped with a servo-motor for accuracy and repeatability. Can easily be combined with Jet-Xtm Slitter for single or multiple in-line slitting.

- Trim tip feeds itself into the trim chute automatically, depending on actual product properties

Proven web production applications include:

Packing material, Fibre cement board, Roofing/Cladding materials, Plastic films, Carbon fibre, Ceiling tiles, Composites (multi-layered with fibre-glass, foam, and cloth), Liquid Packaging Board, Insulation (fibre glass and foam), FRP (fibre glass reinforced polymer), Wet end – fibre board, OSB (oriented strand board) and particle board, Rubber, Acoustic foams, Cellulose sponge and Non woven polypropylene…

If needed, inquire with us for further explanation or click on the box below to determine the best customized water-jet edge-trimming solution for your application.